KeBond Revolutionizes Oil Well Rods with Groundbreaking multi-layer polymer Coating

Lifting Solutions’ Materials Engineer, Karthik Shanmugan, provided insights into the development of KeBond, a revolutionary coated continuous sucker rod poised to transform the oil and gas industry. The idea to develop KeBond emerged in early 2020 with the goal of building upon the success of our original EthyFlex Endless Rod. Development of KeBond commenced in 2021, with commercialization scheduled for 2023.

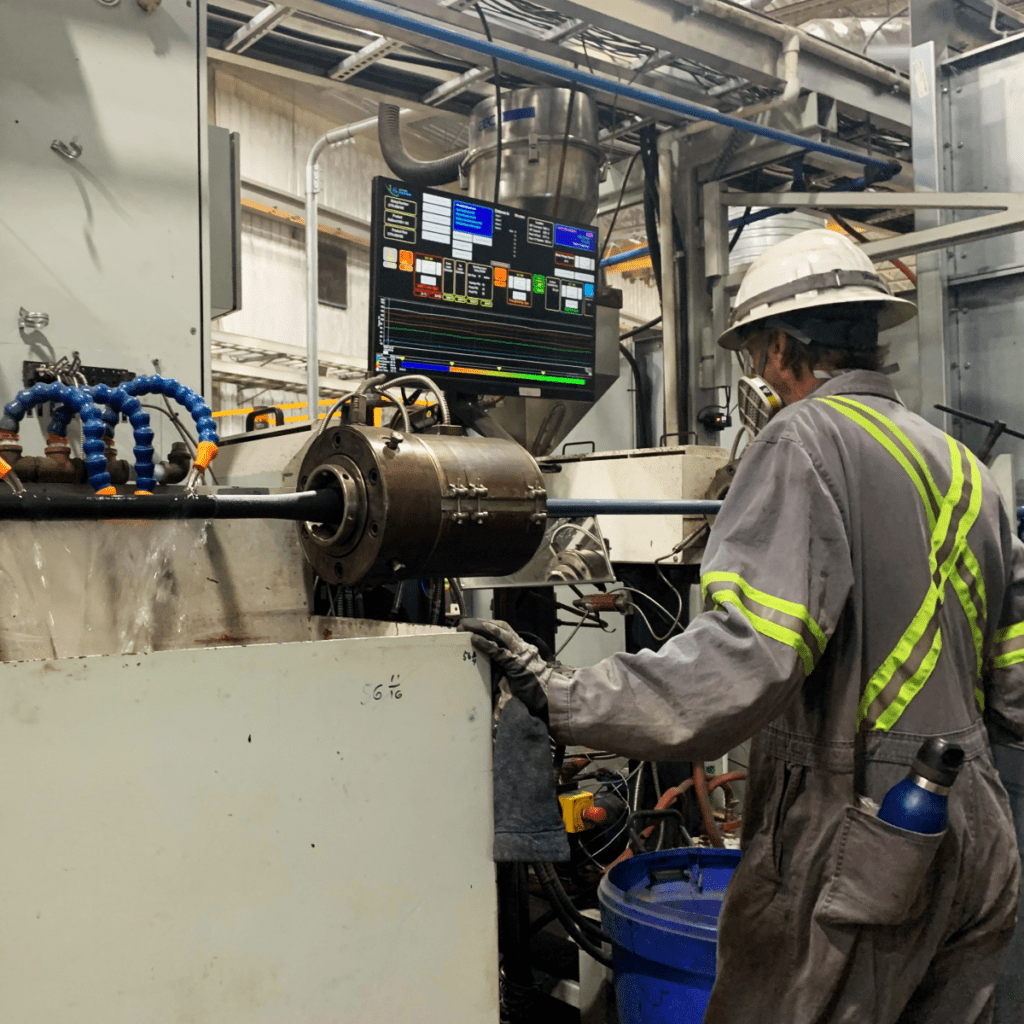

Karthik highlighted the challenges faced by the Lifting Solutions team during the initial stages of KeBond development, which hindered international collaboration and sourcing of essential materials for the proprietary polymer that grants KeBond its unique properties. The Lifting Solutions team overcame these obstacles and, by 2021, acquired a new extruder, marking a significant advancement in our capability to manufacture the KeBond polymer at our Edmonton facility. Over the next two years, our team focused on comprehensive materials testing, optimization of the manufacturing process, and research and development of servicing capabilities.

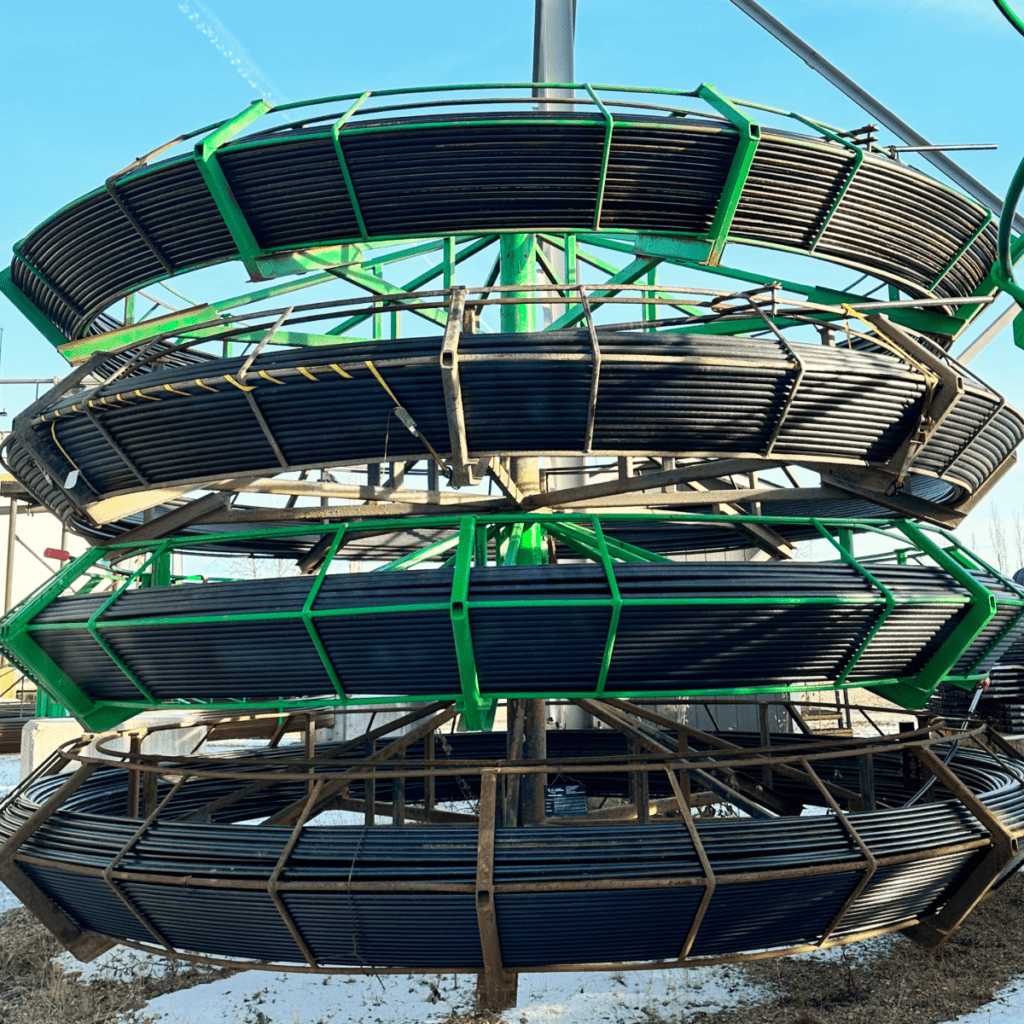

The key differentiators between EthyFlex and KeBond are the coating and bonding. While EthyFlex’s coating is a high-density polyethylene material, KeBond boasts an engineered multi-layer bonded composite thermoplastic coating, applied using a proprietary manufacturing process. This bonded coating not only enhances KeBond’s durability but also allows Lifting Solutions to service string weights of up to 20,000lbs (9091kg) which equates to 7000ft (2130m) of 1in rod, withstand downhole temperatures of up to 80˚C, and endure higher API gravity, corrosive environments. This is a critical improvement as oil extraction increasingly targets deeper, hotter and more challenging wells. Karthik emphasized the importance of the polymer coating in preventing corrosive fluids from reaching the metal surface of the rod, ensuring longevity, and reducing maintenance costs for end-users.

Karthik also addressed the significance of vertical integration, noting that Lifting Solutions manufactures the entire product—from the rod to the polymer coating—and services it, providing a comprehensive solution for clients. Field tests in Canada have shown promising results, with KeBond outperforming expectations. The rod’s longevity and ability to withstand corrosive conditions make it an ideal solution for the evolving needs of the oil extraction industry.

Karthik expressed pride in the Edmonton manufacturing team’s accomplishment with KeBond, highlighting their ability to effectively apply a complex material to continuous rod over extended lengths. KeBond’s success not only represents a technological breakthrough but also underscores Lifting Solutions’ commitment to innovation and addressing the evolving challenges in the oil and gas sector. As the industry shifts towards deeper wells and more corrosive environments, KeBond emerges as a game-changer, offering a cost-effective and versatile solution.