Applications for Progressing Cavity Pump

Progressing Cavity Pumps are a common form of artificial lift to support the extraction of oil and other fluids from a downhole well site.

Designed to Outperform

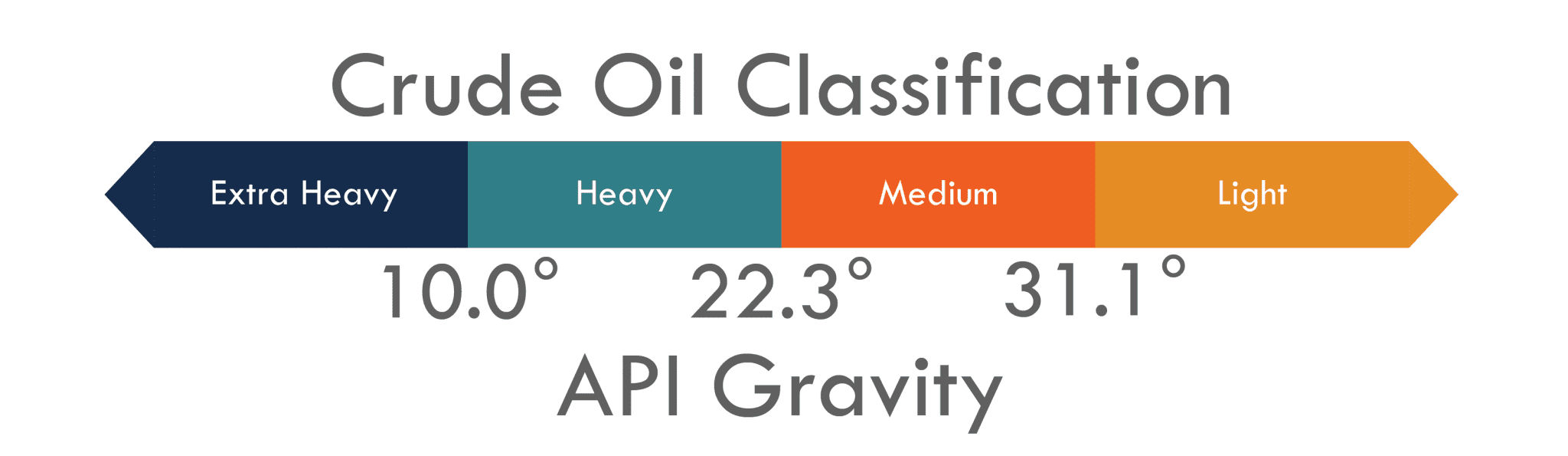

The Lifting Solutions Progressing Cavity Pump, or PCP, comes in over 70 models of various sizes and elastomer formulations, designed and manufactured to meet the toughest wells. Our team of technical specialists reference the American Petroleum Institute API Gravity measure to determine how light or heavy a petroleum liquid is compared to water. From there, they design and recommend the PCP model and elastomer options that are best to support the specific well application and characteristics.

Application Profiles

The following is a summary of some of the most common well application profiles we encounter at Lifting Solutions.

Extra Heavy Crude Cold Heavy Oil Production with Sand (CHOPS)

| CHARACTERISTICS: | Highs Sand Production, 10°API. |

| COMMON LOCATIONS: | Canada |

| CHALLENGE: | Heavy oil is difficult to move as it does not flow well in pipelines. There is a high-level of sand increasing the viscosity of the oil. |

Solutions

PUMPS

Lifting Solutions has engineered specific PCP geometries and elastomers for optimal production of CHOPS wells. The PCP line is appropriately titled CHOPS geometries and currently consists of pumps with a geometry index between 4 to 6. The geometry index is an indication of the aggressiveness and inflow performance of a given PCP geometry. The lower the value the larger the cavity opening, and the shorter the overall cavity length.

ELASTOMER

CHOPS PCP’s are manufactured using SN1 (Soft Medium Nitrile) elastomer. SN1 elastomer has a low hardness with excellent mechanical properties including tear and elongation. It is designed to handle high amounts of abrasives and resists damage from solids. The softer elastomer enables a higher interference rotor fit that allows for significant stator material loss before volumetric efficiency declines.

Heavy Crude Oil

| CHARACTERISTICS: | Up to 22°API, well types include vertical, slant and horizontal. |

| COMMON LOCATIONS: | Canada, Venezuela and Albania. |

| CHALLENGE: | Heavy oils are more difficult to produce and, as a result, recovery rates are driven by technological advancements in production equipment and enhanced oil recovery methods. More recently, drilling technology has resulted in the ability to drill long horizontal wells and in some cases multilateral legs to increase reservoir drainage and recovery rates. |

Solutions

PUMPS

The Lifting Solutions PCP product line has options for cold production. Pump options includes the CHOPS line of pumps from above, and any lower volume, high lift pumps, available in all tube sizes. Pumps should be selected with a low geometric index (between 4–6) to ensure adequate inflow performance. The geometry index is an indication of the aggressiveness and inflow performance of a given PCP geometry. The lower the value the larger the cavity opening and the shorter the overall cavity length.

ELASTOMER

Elastomer selection for heavy oil applications includes HN2, MN1 or SN1.

HN2 elastomer is best suited to warmer climates like in Latin America.

MN1 elastomer is a general-purpose, medium nitrile elastomer with excellent mechanical properties. It has good water resistance and can handle some solids and moderate aromatic levels.

SN1 elastomer has a low hardness with excellent mechanical properties including tear and elongation. It is designed to handle high amounts of abrasives and resists damage from solids. SN1 can be requested in the presence of abrasives where additional interference is required, however, it has slightly inferior mechanical properties and swell resistance. Exercise caution with SN1 elastomer in applications above 15 degrees API.

Medium Crude Oil

| CHARACTERISTICS: | API Classification between 22–31 degrees. |

| COMMON LOCATIONS: | North America, Latin America, India, Africa and the Middle East. |

| CHALLENGE: | Production has its unique challenges inherent with higher water cuts and the inability to adequately move sand. Because the oil in this area contains low molecular weight hydrocarbons, there is more gas in the solution resulting in a higher gas-oil ratio in the produced fluid. Well types include vertical, slant, and horizontal. Like the other applications, drilling continues to advance and companies can now drill long, horizontal wells, and multilateral legs to increase reservoir drainage and recovery rates. |

Solutions

PUMPS

We design and manufacture PCP’s for the effective production of medium crude oils. These pumps are less aggressive than the CHOPS line used to produce heavy oil. The geometry index is normally between 6-20 resulting in transitionary pump geometries that are capable of producing at higher overall rates than their heavy oil counterparts.

ELASTOMER

Elastomer selection for medium crude oil applications is primarily HN1 and HN2 with some applications on the lower end of the API classification utilizing MN1. Higher swell will often lead to excessive stress on the stator-tube bond interface. Whether the application requires the client to use MN1 or HN2 where this phenomenon is mitigated due to lower swell, both elastomers offer excellent stator-tube bond integrity under demanding conditions. This prevents bond failures, which are often catastrophic in nature or will severely impair pump life.

Coal Seam Gas (CSG)

Coal Bed Methane (CBD)

| CHARACTERISTICS: | These drilling applications focus on dewatering coal seams to release methane gas. They start with a low gas-water ratio which increases over time as water is removed from the depressurized reservoir. Initial operation requires continuously producing water at low bottom hole pressures until gas rates increase. |

| COMMON LOCATIONS: | USA, Australia and India |

| CHALLENGE: | Abrasive production and stick-slip in a low lubrication environment is challenging and requires proper elastomer and fit selection. Consistent flow is required to promote gas production (escape) from the reservoir. |

Solutions

PUMPS

Progressing Cavity Pumps’ simplicity, ability to handle coal fines, and require very little maintenance make them the system of choice. They also produce a wide range of rates with a non-pulsating flow. It is critical to keep these wells pumped off to maintain a low bottom hole pressure and allow the gas to escape the formation.

Lifting solutions manufactures many low-volume small-form factor PCPs specifically for CSG/CBM applications. Rotor and stator fit are critical to ensure pump operation in an environment void of lubrication pumping mostly water at low viscosity (1cp) with coal fines. Lifting Solutions uses specialized sizing tools to determine the best rotor size for the applications based on elastomer and fluid characteristics.

ELASTOMER

MN1 elastomer is the best choice in high water cut applications due to its mechanical properties, low water swell and excellent hot water bond integrity.

Light Crude Oil

| CHARACTERISTICS: | API Classification greater than 30 degrees with an oil density less than 870kg/m3. |

| COMMON LOCATIONS: | Northwest Alberta, West Texas, Williston, North Dakota, Southern Saskatchewan, and Estevan |

| CHALLENGE: | Directional drilling advancements and hydraulic fracturing technology enable wells with low permeability to be produced effectively including shale oil and oils produced from the Bakken formation in the US and Canada. Wells include vertical, slant, and horizontals with large multi-leg, multi-stage fracking programs required to enable production. |

Solutions

PUMPS

Lifting Solutions has an array of geometric and pump volume options to produce light oil. These pumps are generally less aggressive with a geometry index greater than 20. These pumps are capable of producing at high flow rates, and, because of the low viscosity and high mobility of the oil, they can move fluid efficiently.

LS uses specialized sizing tools to determine the best rotor size for the applications based on elastomer and fluid characteristics.

ELASTOMER

Elastomer selection for light oil applications is primarily high nitrile – HN2. Due to the aromatic content, care must be taken with the application of any elastomer where the API Gravity is above 30 degrees. A fluid compatibility test is required to ensure proper elastomer selection. A loose, swell accepting rotor/stator fit is essential based on the anticipated swell.

High Volume Lift, High Water Cut (HVL)

| CHARACTERISTICS: | It is common to have pockets of bottom-hole water in many heavy, medium, and lift oil applications. Continued production of these wells results in high volume production requirements with >95% water cut. These applications require large-volume pumps operating at high speeds to produce massive amounts of fluid emulsion that is primarily water with a small percentage of oil. Due to the nominal pump volume and required lift, the overall torque requirements are high when producing at high rates. The horsepower equation brings speed into consideration resulting in high horsepower requirements. |

| COMMON LOCATIONS: | Australia and India. |

| CHALLENGE: | Applications include wellbores with vertical, slant, and horizontal drilling completions. They are typically mature wells where production has come into contact with bottom water pools over time. |

Solutions

PUMPS

PCP selection includes pumps with a higher geometric index to facilitate the production of high volumes. These pumps are generally longer pitched, less aggressive models that will move water efficiently at high speeds/rates but would struggle with higher viscosity fluids at high speeds due to poor inflow performance.

ELASTOMER

Elastomer selection defaults to MN1 medium nitrile elastomer and moves towards HN1/HN2 high nitrile elastomer as a function of the oil API gravity. It is important not to disqualify MN1 elastomer in this high water cut applications as it has superior mechanical properties and the best water swell resistance. Only when the API Gravity is above 20–25 degrees or due to high CO2 gas in the produced fluid should the high nitrile elastomers be evaluated. The decision to move to a high nitrile elastomer should be based on elastomer/fluid compatibility testing with the appropriate rotor/stator fit selection to accommodate both water and aromatic swell.

Related Products

Let’s solve your lift challenges.

Reach out and Experience Performance with Lifting Solutions.