Coated Endless Rod™

The Lifting Solutions Coated Endless Rod™ (CER) is a truly innovative corrosion protection solution. Engineered and designed to combat specific, yet common, jointed and continuous sucker rod failures, the CER provides a barrier of protection to increase performance.

In challenging well conditions, and because of the cyclic loading nature of rod-driven artificial lift equipment, crack propagation to failure through fatigue occurs. Crack initiation can occur on jointed or continuous sucker rod surfaces due to corrosion, and stress risers.

Lifting Solutions’ Coated Endless Rod™ products are the solution to combat these failures head-on.

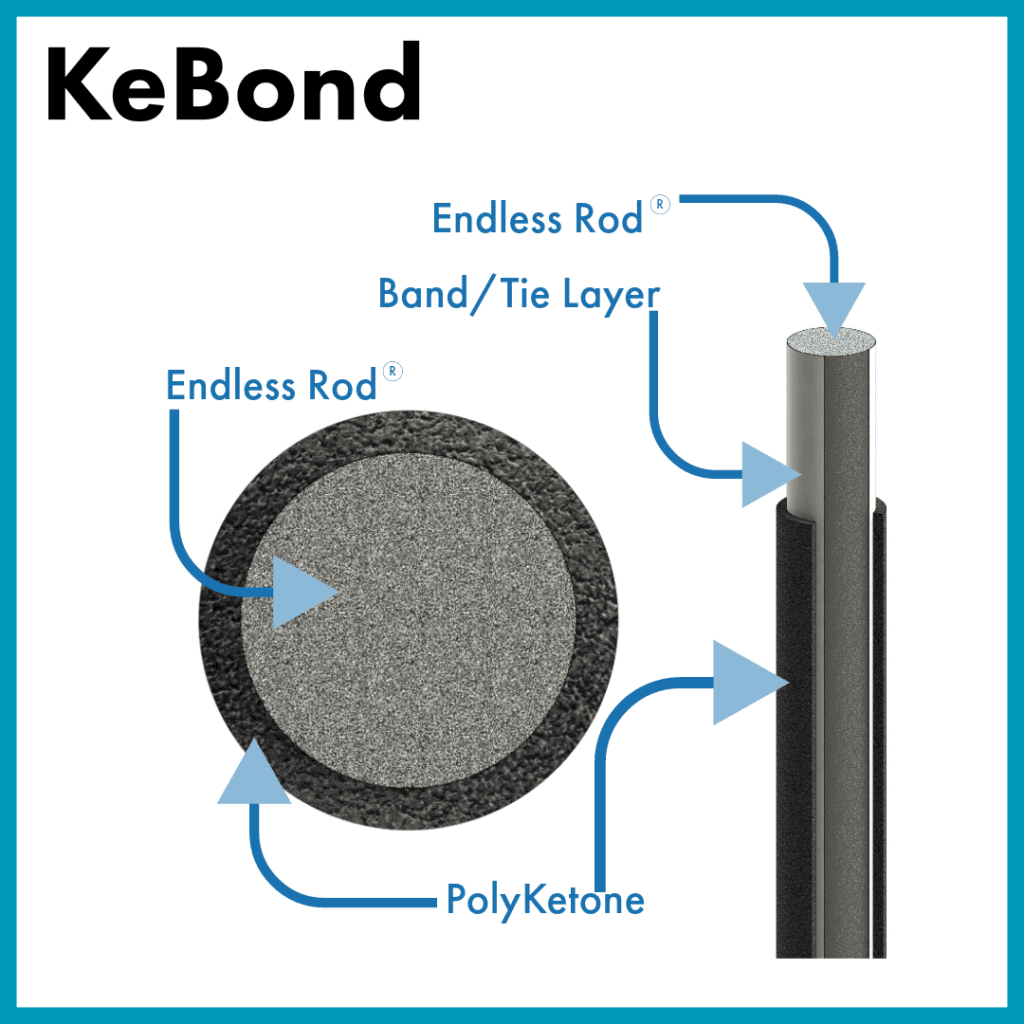

KeBond™

Enhanced corrosion protection.

Lifting Solutions' KeBond™ is the next generation of Coated Endless Rod™. Specifically engineered to withstand hotter and deeper wells, the KeBond™ technology is a bonded composite design featuring an engineered thermoplastic and Polyketone outer coating. Bonded to the bare rod, KeBond™ delivers high performance in corrosive PCP and RRP applications.

Performance: Lifting Solutions conducted laboratory, durability and field trials to assess the performance of KeBond™. As the results steadily arrived, it became evident that KeBond™ stands out as the superior coated rod product to protect against corrosion and wear. We continue to expand field trials as well as limited commercialization in Canada and are in the initial stages of field trials in the USA and other international locations.

EthyFlex

Protect from corrosion and wear.

Lifting Solutions' EthyFlex has a polymeric coating, that is engineered to shield the underlying bare rod from corrosion and wear. This fit-for-purpose product, EthyFlex ensures rod integrity and increases performance in corrosive and abrasive environments.

As an added benefit, once the coating is worn, the EthyFlex continuous sucker rod can be stripped using our patent-pending Coated Rod Stripper and redeployed as a bare Endless Rod™ continuous sucker rod.

Performance: In an 80-well pilot project on one site, the client saved over $3.5 million in servicing costs after installing Coated Endless Rod™ continuous sucker rod.

Metallurgies & Sizes

To ensure that EthyFlex is fit-for-purpose for every application, our coated products are available in all grades and sizes of our bare Endless Rod™ product.

Servicing Coated Endless Rod™

To ensure product integrity, Lifting Solutions has engineered fit-for-purpose specialized fleet equipment to service our coated rod without damaging the coating. Our gripper blocks, field welding equipment, and coating repair tooling are engineered to deliver the quality performance our clients expect to experience when they work with the Lifting Solutions team.

Let's solve your lift challenges.

Reach out and Experience Performance with Lifting Solutions.