PCP Manufacturing

LIFTING SOLUTIONS PROGRESSING CAVITY PUMPS are

ISO 15136-1 and ISO 9001:2015 certified.

Innovation and quality

Manufacturing Progressing Cavity Pumps (PCP) takes time, precision, and experience. Our team has developed high quality, automated processes to effectively manufacture our Progressing Cavity Pumps 24/7 to meet our clients’ needs.

Our Team

Lifting Solutions has one of the most experienced PCP systems teams, globally. From engineering and elastomer development, research and development, manufacturing, applications, field distribution and pump shop bases, and technical sales, we understand PCPs. That is why we are one of the top Progressing Cavity Pump manufacturers in the world.

Optimize performance

Our PCP manufacturing facility has a designed output capacity of 10,000 per year. This incredible manufacturing capability is because of our rigorous process control and focus on optimizing production.

When our engineering team is designing a PC Pump, they work with the manufacturing team to ensure the plant and equipment are ready for production leading to an optimal tube and bar selection. This reduces production costs and increases efficiency, saving our clients money.

The Facility

Our facility incorporates all operations for the PCP manufacturing system and a complete end-to-end process. From raw elastomer, tube and bar materials, rotor and stator component manufacturing, through to the complete assembled pump; our team delivers up to 14,000 assembled PC Pumps per year from our Canadian facility.

A strong collaboration process between the teams allows for a high level of efficiency, reduced lead times, and a quality product. Our team manufactures over 40 different pump geometries in three (3) elastomers. We have the latest manufacturing technology including custom equipment and processes. Our team has put into place automation processes to support the safety, quality, and efficiency of our operation.

Technology

Our manufacturing facility is equipped with state-of-the-art equipment including two Weingartner machines. The Weingartner is the ultimate whirling and milling machine. It combines precision-controlled machinery with performance-based software that allows our Lifting Solutions technicians to optimize the production of all extrusion and injection moldings for our PC Pumps. This system is the best in the industry, and we have the most experienced technicians working with this machine.

The Process

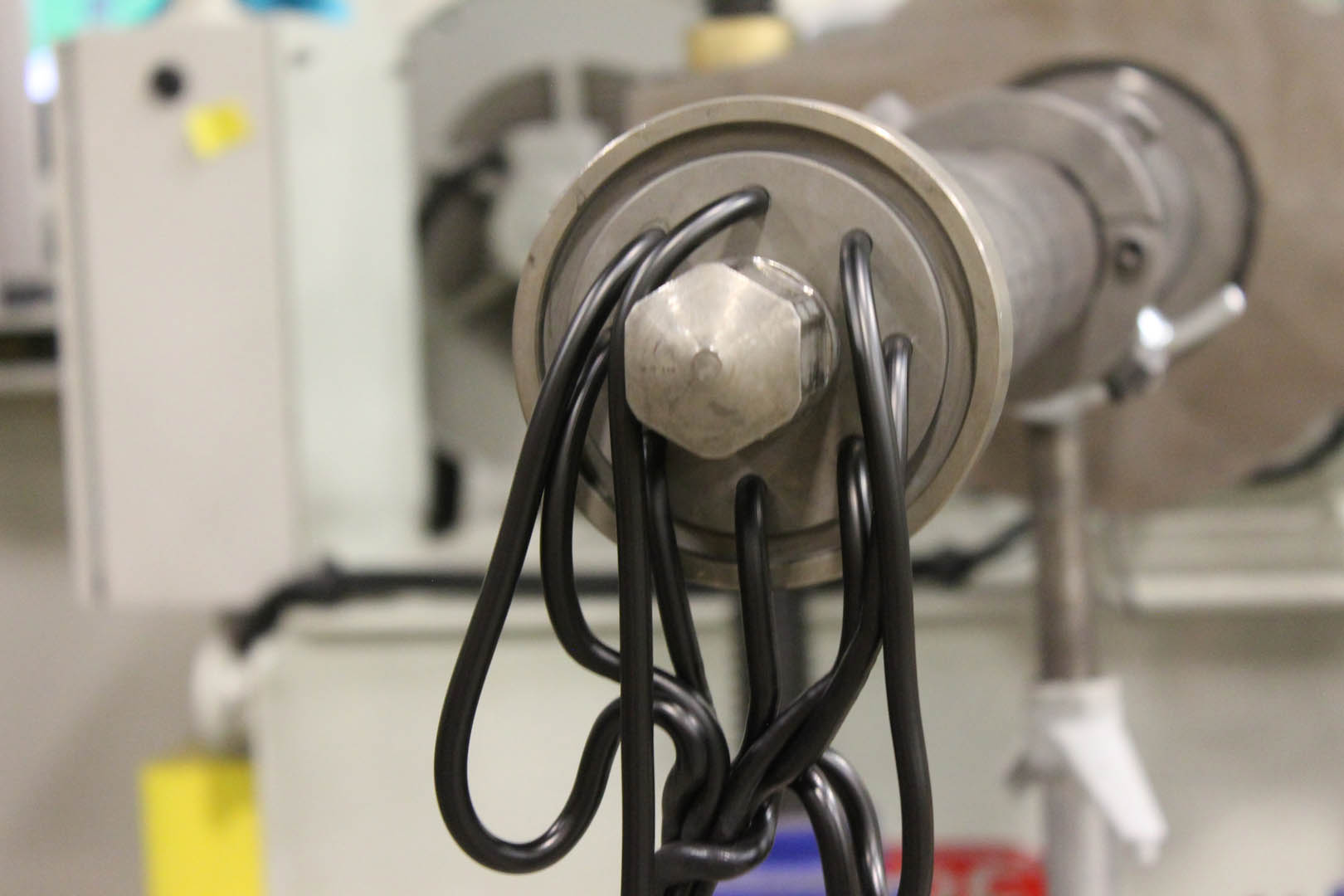

Progressing Cavity Pump manufacturing is composed of two parts: the rotor and the stator. Each step involves specialized calculations that are used from unique well conditions. Lifting Solutions produces fit-for-purpose geometries, optimized tubing sizes, and balanced compression fit, to ensure our PC Pumps exceed industry quality standards, while lowering our clients’ lifting costs.

An internally developed Lifting Solutions integrated Manufacturing Execution system communicates the required information to the shop floor and collects critical information on the manufacturing process and product parameters. Together this provides for detailed traceability and supports ongoing continuous improvement efforts.

In support of delivering high-performance products, there is an emphasis on quality within the PC pump manufacturing facility. Given the nature of the stator product limits inspection options, the approach is to build quality into the process. This process control is supplemented with key product inspections with the ability to achieve the highest Q1 level of the ISO 15-136-1 standard.

Let’s solve your lift challenges.

Reach out and Experience Performance with Lifting Solutions.