Inspection and Failure Analysis

At Lifting Solutions our people and processes make the difference behind our products. We commit time and resources to thoroughly inspect and test our products so we can deliver on our promise to outperform the market.

Data-Driven Performance

Lifting Solutions conducts product inspection and detailed failure analysis on all our products. Our team of engineers, technicians, and application specialists use the data to find ways to improve existing products and develop new ones. Our team uses the data to build technical bulletins and other data-rich information so we can make reliable choices and product solutions that our clients can trust.

Progressing Cavity Pump Inspection Overview

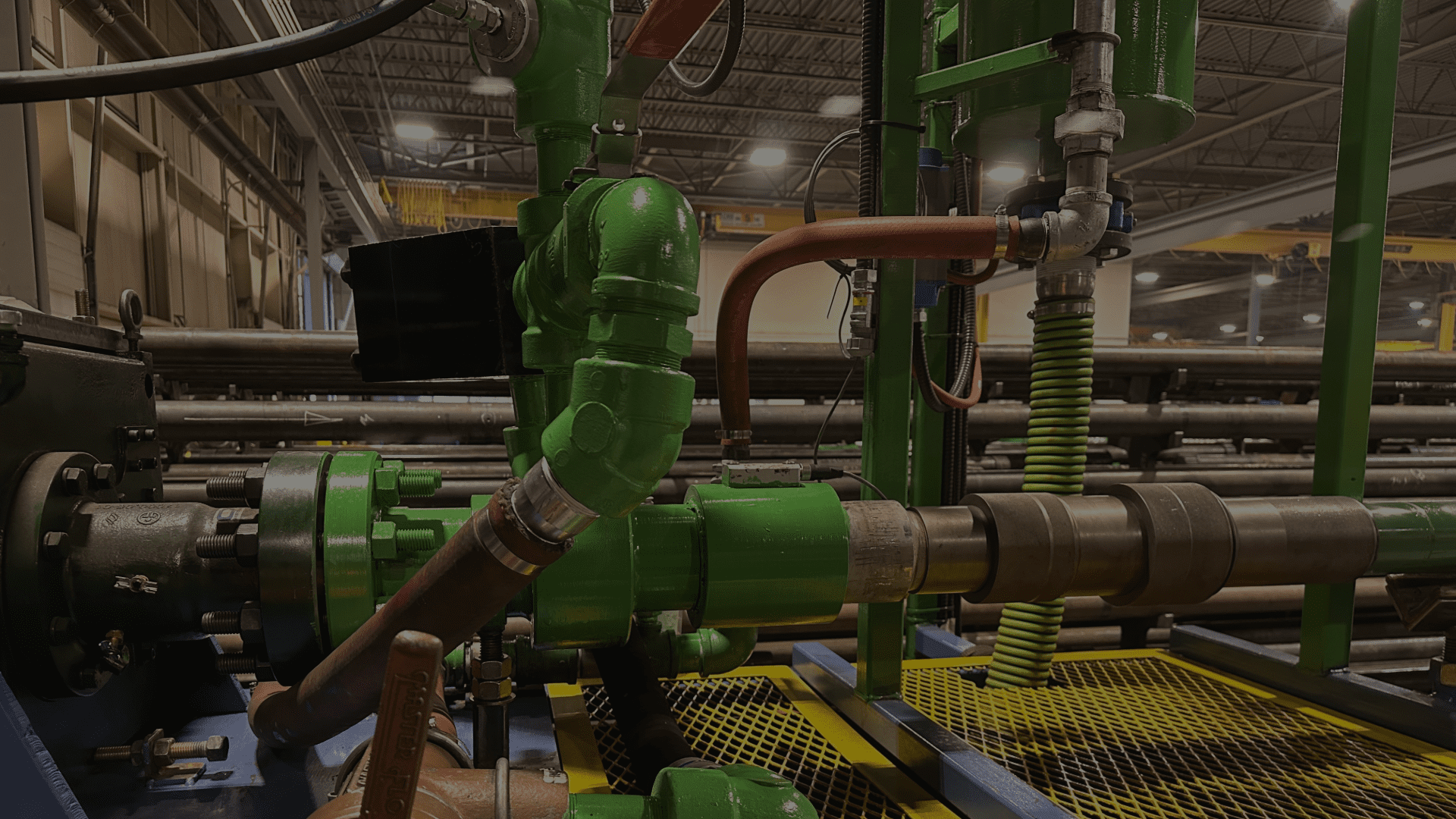

When it comes to Progressing Cavity Pumps (PCP), where we offer a wide variety of product configurations to combat some of the most challenging applications across the world, inspections and analysis are critical to performance. We have a dedicated team and a full materials lab where we complete a variety of product tests.

Lifting Solutions conducts product inspections, including detailed failure analysis, to optimize product performance and direct continuous product improvements and new product developments. These processes are particularly valuable for PCPs due to the wide variety of product configurations and often challenging nature of the wellsite applications.

Lifting Solutions has three inspection levels with different activities and associated objectives.

Level 1: Field Inspection

Level 1 (L1) inspections are performed by our pump technicians at field service base locations. Our technicians’ primary objective is to quickly characterize the condition of pulled pumps and enable decisions on the disposition of the rotor and stator components in terms of reuse, repair, or discard.

The L1 inspection is normally limited to a visual inspection to characterize the condition of the components including any damage. If it identifies that the pump is potentially in usable condition, a pump retest is normally conducted to quantify hydraulic performance. Although a relatively cursory inspection, in the case of a failure, attempts are made to identify the primary failure mode and, where evident, the root cause and contributing factors. L1 inspection information is managed within the Lifting Solutions Product Tracking System which generates a standard inspection report and enables analysis and reporting on inspection trends.

ROTOR INSPECTION

The L1 inspection of the PCP rotor is concentrated on the chrome coating condition – specifically, loss of material, cracking, pitting, and heat checking. If there is significant loss or damage to the coating, then the rotor is closely examined to determine if the underlying base metal has been compromised; in which case, the rotor is usually not a candidate for re-chroming. The rotor top connection is inspected with a focus on the threads and the transition area to the profile. Although measurements are not conducted in an L1 inspection, pictures may be taken to illustrate severe or abnormal damage.

STATOR INSPECTION

A L1 stator inspection starts with a visual inspection of the outside stator condition including threads and an initial look from the ends into the inside of the stator. If the end examination detects damage to the elastomer lining, then we may use a borescope camera for closer examination including further into the stator length. Since the L1 inspection is non-destructive, even with the field borescope, the assessment detail of the elastomer condition is limited. It is limited to identifying common external (such as corrosion, hole in the stator, bent, and broken) and internal (such as abrasive wear, cracking, chunking, burnt, pressure washing, and blistering) damage modes at approximate locations along the stator length. Like the rotor, dimensional measurements are not performed at this level of inspection, but pictures may be taken via the borescope camera.

Level 2: Engineering Non-Destructive Inspection

Level 2 (L2) inspections are performed at the Lifting Solutions Edmonton manufacturing facility by our engineering team. L2 inspections are similar to L1 inspections in that they are non-destructive but differ in that several specialized tools are used to complete a more comprehensive evaluation including dimensional measurements.

Most commonly, L2 inspections are performed to support field testing of new products or special application reviews where information on the pump condition is required while keeping the pump intact for a rerun. These inspections are typically completed within a few days and the pump is returned to the service base. Depending on the findings, an L2 inspection may progress to an L3 inspection (below). L2 inspections are usually completed in conjunction with a review of the application and operational information, given that they are normally associated with a performance assessment. L2 inspections are documented in a report that provides pump specifications and critical manufacturing parameters, a summary of any available well history/operating conditions and application reviews, the inspection results, and interpretations and associated recommendations.

ROTOR

The rotor minor and major diameter is measured at multiple locations along its length and compared to the as-manufactured dimensions. A detailed visual rotor inspection is completed, including taking photographs of areas of interest. Depending on the situation, supplementary non-destructive rotor inspection elements may include 3D laser scans of the rotor profile, coating thickness measurements, coating integrity tests, chemical spot tests, liquid penetrant inspections (LPI), chrome/fracture surface inspections using an optical microscope and weld inspections.

STATOR

The stator minor diameter is measured at every pitch along its length and compared to its as-manufactured profile. An external inspection of the stator is completed, and a high-resolution borescope camera is used to review the internal stator profile and capture images of critical areas. Depending on the situation, other non-destructive inspection elements may include stator centralization inspections, screwdriver tests for visual elastomer detachment at both ends of the stator (cutbacks), and weld inspections.

Level 3: Engineering Destructive Inspection

Level 3 (L3) inspections include all elements of an L2 inspection plus destructive evaluation and associated detailed examination of the stator at the Lifting Solutions Edmonton materials laboratory. L3 inspections are performed to evaluate short runs or failures but may also be done as part of new product field testing evaluations.

The objective is to find the nature of the damage inside the stator that could not be identified in the L2 inspection (such as elastomer detachment, cuts, hysteresis, swell, hardening, and tears), determine the failure mechanism and the root cause and, and when applicable, provide recommendations for corrective actions. Normally, L3 inspections are accompanied by a detailed review of the well history and operational data, and a progressive evaluation typically varies depending on findings. L3 inspections take several weeks to complete, and the findings are documented in a formal report.

Destructive stator analysis involves removing short sections from the stator in regions of interest and slabbing them in half to allow close examination including high-resolution images. Bond samples are removed from representative locations and subjected to push-out, centralization, and hardness testing to assess bond and elastomer integrity relative to as-manufactured conditions. Samples of elastomer are usually removed and subjected to internal tests (such as dry-out and flame tests) and, where required, third-party tests to assess mechanical properties and solid, liquid, and gas penetration. When significant elastomer material loss is observed, a 3D laser scan may be taken off of the stator internal profile to quantify the change in shape relative to the as-manufactured condition.

Let’s solve your lift challenges.

Reach out and Experience Performance with Lifting Solutions.