PCP Systems

With fit-for-purpose geometries, optimized tubing sizes, and balanced compression fit, your Lifting Solutions pump exceeds industry quality standards and has the proven performance to lower lifting costs.

Benefits

Lifting Solutions manufactures the stator (stationary component) and the rotor (rotates the pump) in our 75,000 sq ft manufacturing facility in Edmonton, Alberta Canada. We manufacture a variety of sizes from 2m3/day per 100 rpm, right up to 280m3/day per 100 rpm.

Vertical Integration Manufacturing

Our PCPs are manufactured and designed in a vertically integrated system. Our engineering, research and development, and manufacturing teams are under one roof. The level of collaboration and ability to adjust and innovate in real-time is what makes Lifting Solutions stand apart from the rest.

Quality Design

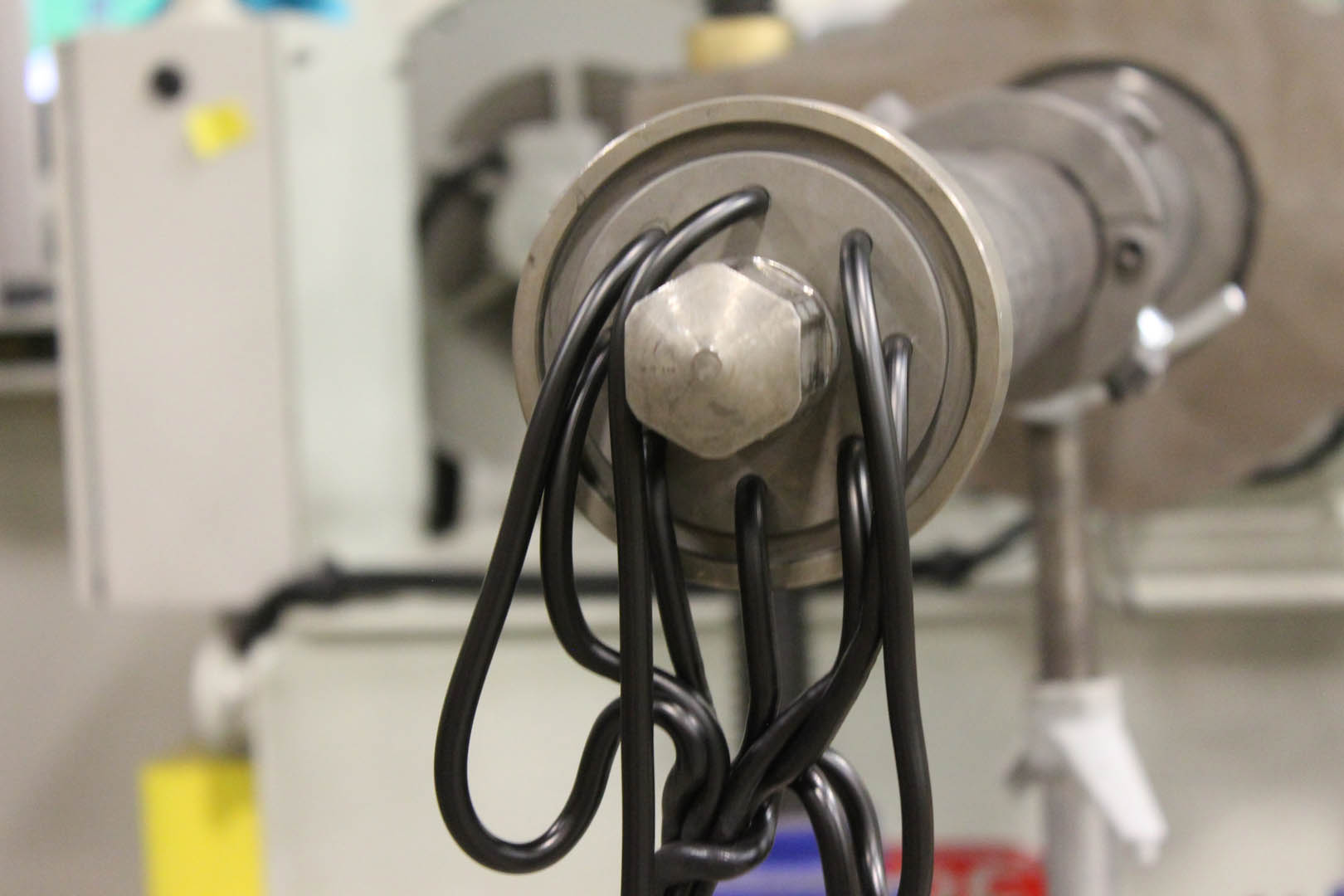

Lifting Solutions stator is injected with an elastomer material and bonded inside the steel tube. The stator is directly threaded so there is no welding needed, reducing costs and potential failure locations on the pumps. The rotor is chrome coated for wear resistance. Together, the Lifting Solutions pump continues to outperform the market and is working across the globe in a variety of applications.

Fit-for-Purpose System

Our PCP system is designed with fit-for-purpose geometries to accommodate common casing and tubing sizes without the need for special accessories. This also allows our artificial lift specialists to understand the well challenges and then design and recommend the appropriate solution. We also complete full-scale durability bench testing on every pump.

Progressing Cavity Pump Elastomers

One of the most important parts of a PC Pump system is the elastomer. That is why Lifting Solutions has a dedicated team of materials engineers and technicians who continue to innovate our elastomers to provide options for various well conditions to enhance performance.

Innovative R&D

Our team takes a leave-no-stone-unturned approach when it comes to formulation development, manufacturing, quality control, elastomer selection, and application. Why? Because, it is common to have poor PC Pump performance because of the elastomer, or the elastomer-to-tube bond system.

Our dedication continues to pay off as we have a selection of high-performing elastomers with a proven history.

For detailed information on our elastomers, please download our complete elastomer datasheet.

Elastomer Selection

It goes without saying that applying the right elastomer to a client’s need is key to successful pump performance.

Our materials engineering and technician team often use elastomer-fluid compatibility tests, performed in our Research & Development facility to produce fluid samples collected from clients. The test simulates and accelerates the fluid impact on elastomers, which are measured for volume change and mechanical property changes. This information allows our team to narrow down the elastomer choice and provide critical information for pump fit selection for our clients.

To fully understand elastomer swell and selection for your downhole scenario, please reach out or visit our technical bulletin library to read our resources targeted at major application groups.

Lifting Solutions is fully compliant with

ISO 15136-1.

Related Products

Let’s solve your lift challenges.

Reach out and Experience Performance with Lifting Solutions.