Materials Development

Materials are at the core of Lifting Solutions’ two primary product lines and play a dominant influence on our product performance and longevity. We are proud of our technical and engineering capabilities that continue to develop innovative solutions that outperform the market.

Our Approach

Lifting Solutions’ research and development activities revolve around materials development and the design of specialized manufacturing processes associated with these materials to yield optimal products. This work is led by specialized chemical, polymer, and metals engineers with advanced specialized degrees and supported by a team of technologists and technicians to aid with extensive small and full-scale testing, and product inspections.

PCP Elastomer

Progressing Cavity Pumps require specialized material development for the stator elastomer and associated bond system, as well as for the rotors base material and coatings.

Stator Elastomer Development

Elastomer formulation development is a complex exercise requiring advanced elastomer chemistry and design of experiments, and the necessary laboratory equipment. Lifting Solutions has in-house elastomer experts who excel in the challenge by utilizing our comprehensive elastomer testing equipment.

The elastomer development process is a critical step and requires a few important steps pre and post development. These steps include the development and detailed understanding of the elastomer’s target applications, transforming them into functional requirements, testing the developed elastomer in an actual PC Pump in a durability test bench, developing manufacturing process specifications, and a careful field trial management process.

The PCP elastomer development process at Lifting Solutions is seamless and carried out with the utmost diligence, thanks to the rich experience of our Research & Development, and application engineering teams.

Bond System Development

While the presence and impact of the bond system used to adhere the elastomer to the stator tube is invisible, its robustness is critical to avoid infantile failures and achieve long-term performance.

The bond system development is an integral part of Lifting Solutions’ elastomer development process. Development starts with choosing compatible adhesives from leading rubber-metal bonding agent suppliers. Our technical specialists then customize the elastomer formulations to achieve desired bonding properties for satisfying the most demanding application conditions. The in-house knowledge of stator bond degradation mechanisms, an automated and advanced manufacturing process, and quality control ensures ensure that the elastomer-tube bonding of our stators is unmatched in quality, consistency, and performance.

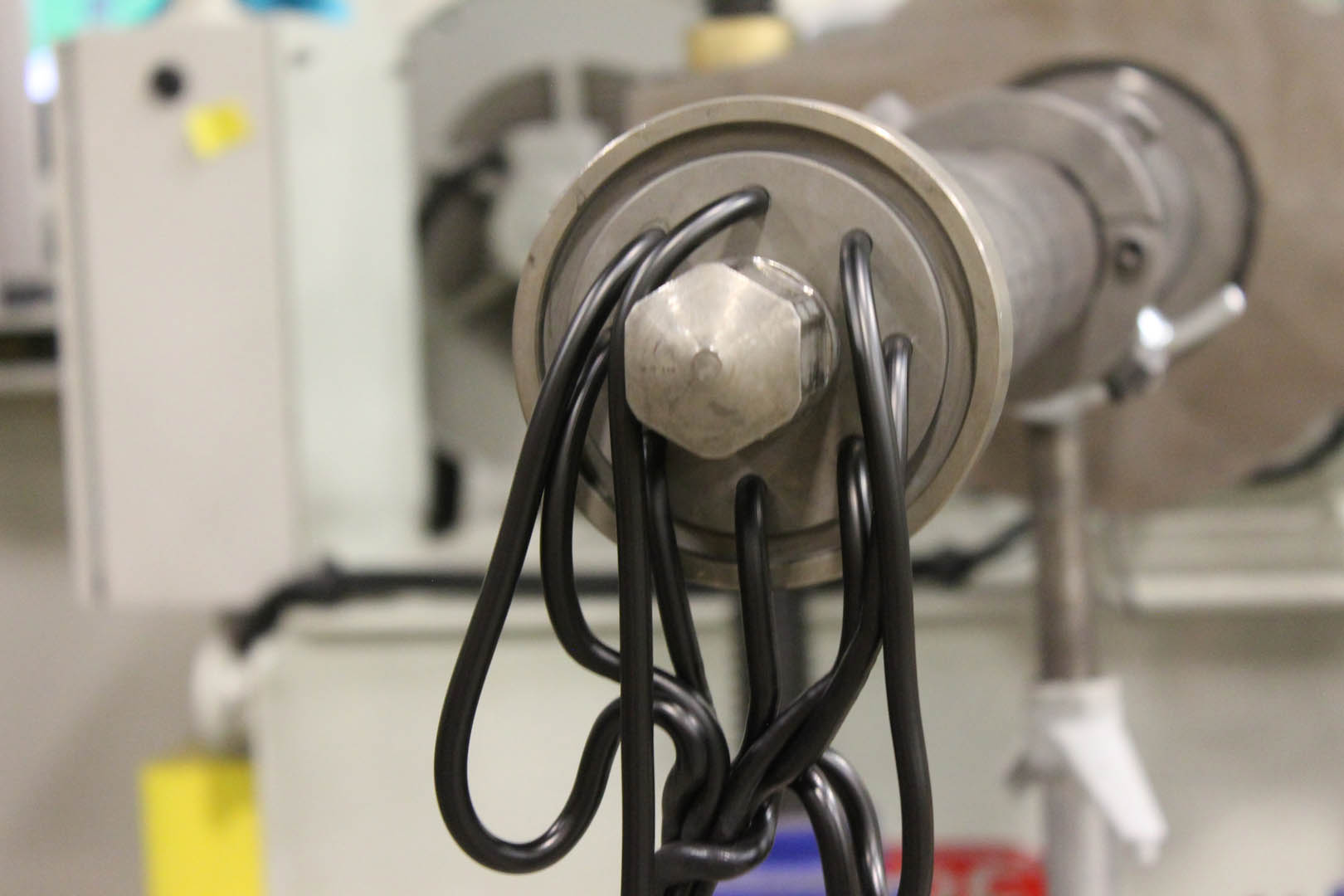

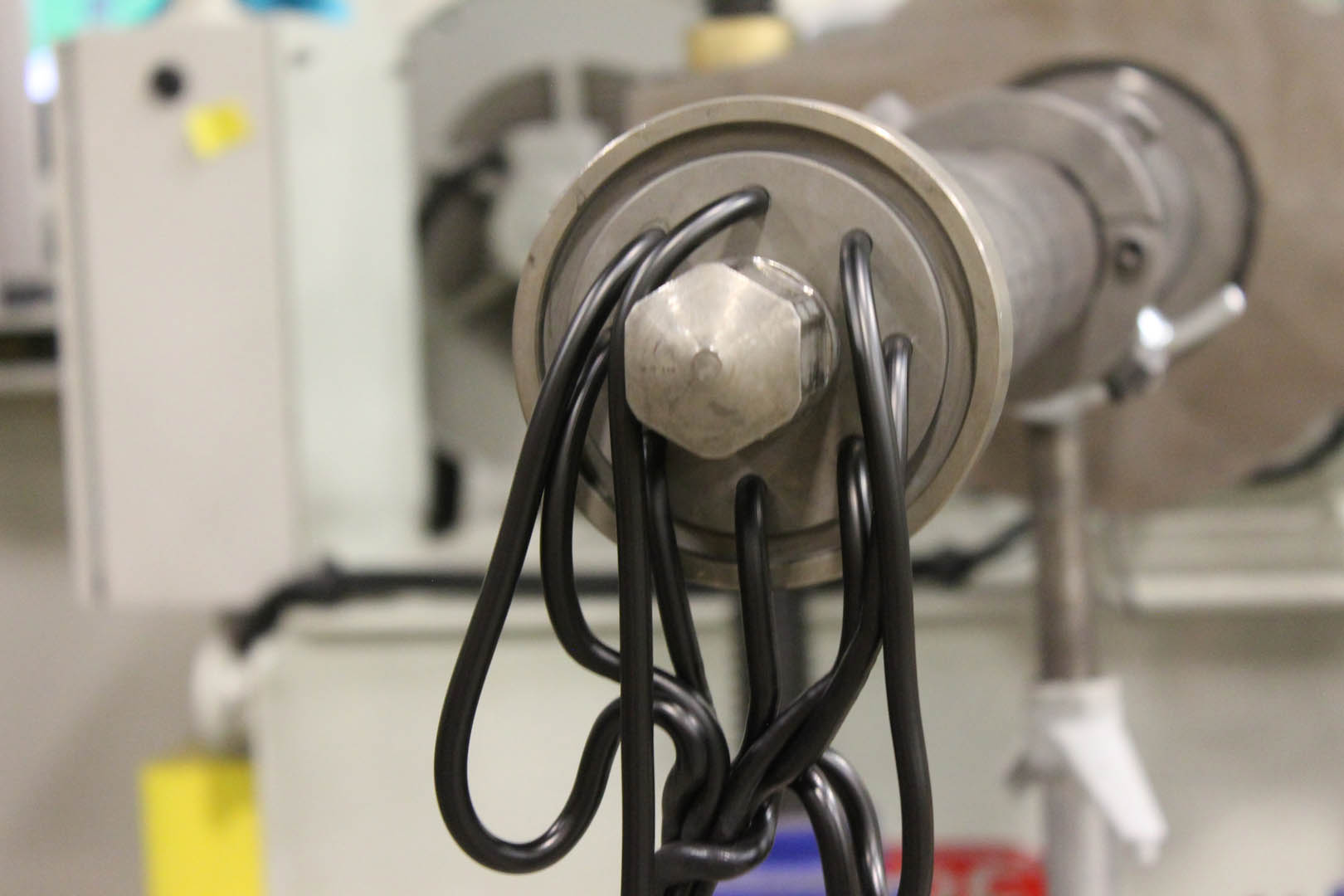

Coated Endless Rod

Lifting Solutions is proud to present the EthyFlex Coated Endless Rod to the market today. Our team of skilled chemical, polymer, and metals engineers has developed exceptional coatings for these products, ensuring their outstanding performance even in the most demanding well applications.

Related Technology

Let’s optimize your well.

Connect with our client solutions team and Experience Performance.