PivotAL PC Pump Model 10-1200×2 in 100 12-05

Project Information

| Location: | Lindbergh, Alberta, Canada |

| Field Application: | CHOPS (Cold Heavy Oil Production with Sand) |

| Products: | PivotAL Progressing Cavity Pump* |

| Install Date: | April 2018 |

Client Challenge

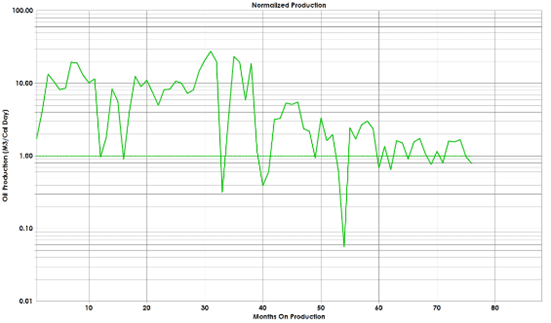

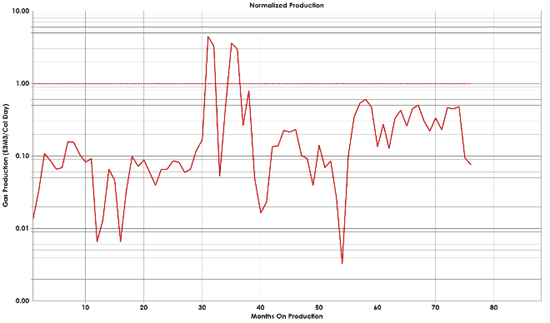

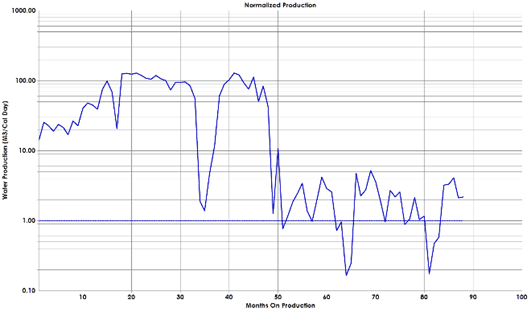

In a CHOPS (Cold Heavy Oil Production with Sand) application near Lindbergh, Alberta our client selected a low inflow, mature well that had been on production for close to 75 months. The well had been in production since its completion in 2005. Originally the well came on and produced between 10-18m3 of oil daily for the first 40 months. The well declined over the next 30 months and settled in closer to 1-2m3 of daily oil. Water production also declined over the initial 80 months.

Compounding inflow issues resulted in numerous burnt pumps, shortened mean time to failure and expensive workover frequency.

Client Goal

The previous two Progressing Cavity Pumps (PCP) installed, ran for 120 and 30 days. Based on an average run time of 75 days, the yearly workover frequency was just under 5 workovers per year. At a normalized workover cost of $20,000 this marginal well was quickly becoming uneconomic.

In order to keep this well producing, the workover costs needed to be reduced significantly.

Our Solution

Lifting Solutions proposed a PivotALTM PC Pump to help cut down on the tubing pull frequency ultimately aimed at reducing workover costs.

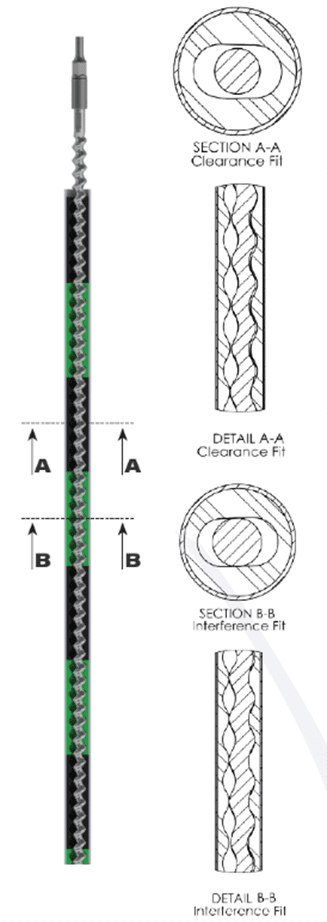

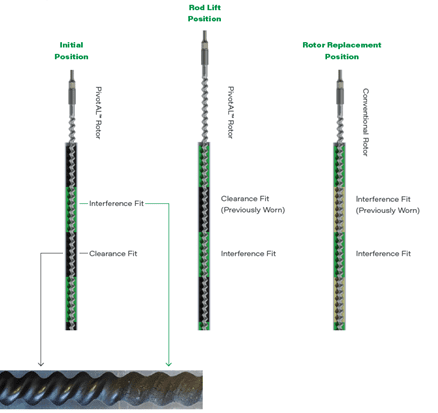

This patent pending pump technology allows for a rigless pump restoration by selectively being able to reposition active and inactive sections of the rotor inside the stator between workovers.

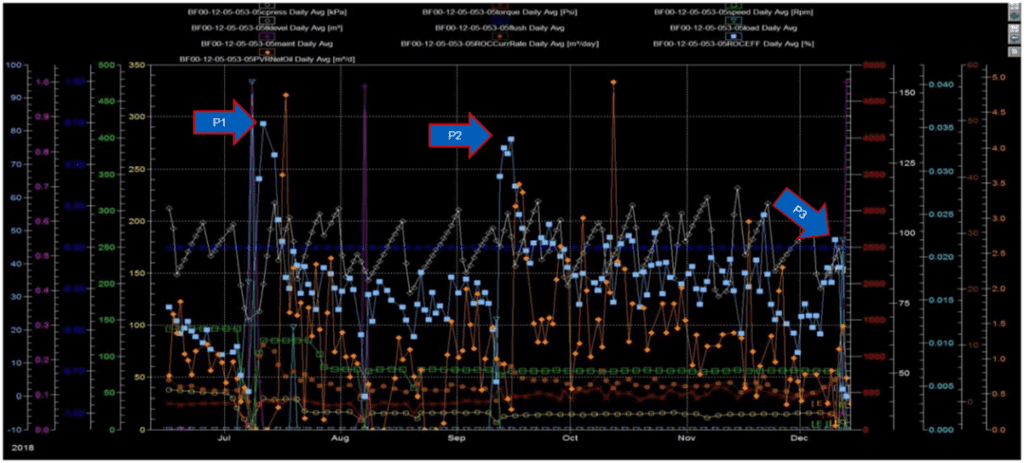

The PivotALTM PCP was installed on April 9, 2018 and ran successfully for a total of 305 days. During this time the rotor was lifted 3 different times each resulting in an uptick in pump efficiency, as expected. The following table summarizes the different operating positions, run time, lift distances and result.

| POSITION | LIFT DATE | RUN TIME | LIFT DISTANCE | EFFICIENCY COMMENTS |

|---|---|---|---|---|

| P1 | APRIL 9, 2018 | 121 DAYS | Started at 80% efficient | |

| P2 | JULY 10, 2018 | 62 DAYS | 10 INCHES | Lift restored efficiency from 30% to 75% |

| P3 | SEPT 12, 2018 | 101 DAYS | 8 INCHES | Lift restored efficiency from 20% to 50% |

| SHUT IN | DEC 13, 2018 | – | – | Efficiency was at 20%. Worn Pump. Workover was delayed due to Alberta curtailment production cuts |

| P4 | SEPT 12, 2018 | 21 DAYS | 6 INCHES | Final lift attempted, ran at 20% for 3 more weeks |

Scada Trends

Scada trends covering the production timeframe clearly show the efficiency improvements corresponding to each rotor lift.

Conclusion

The installation of the PivotALTM pump was considered a technical success as the pump efficiency was restored via several rod lift operations. Overall, the lift sequencing was out of synchronization with the intended 12” lift option, however there was a clear improvement in pump efficiency at 10” above the initial landing position as well as at 18” above the initial position. Before pulling the tubing to complete the final pump change, the client made one last effort at producing the well after doing a third lift.

Ultimately, the run life increased to just under one-year, successful rotor lifts contributed to increasing longevity of the pumping system and the workover frequency was reduced to 1.2 workovers per year down from 5.

Let’s solve your lift challenges.

Reach out and Experience Performance with Lifting Solutions.