KeBond™ RRP Performance Success in Estevan

Project Profiles

Project Information

| Client Name: | Confidential |

| Location: | Estevan, Saskatchewan, Canada |

| Application: | Corrosion |

| Initial Install Date: | KeBond Endless Rod™ October 9, 2024 |

| Product: | 7/8 ND Grade KeBond Coated Endless Rod™ |

Client Challenge

This case study explores the deployment, performance, and benefits of the KeBond™ coated continuous rod in a reciprocating rod pump (RRP) application in the shallower Canadian portion of the Bakken play. It highlights the rod’s durability in aggressive environments, the root causes of historical failures, and the successful implementation of KeBond™.

KeBond™ was introduced to address recurring failures in traditional rod strings mainly due to corrosion-induced fatigue. In this application, the rod string history from 2019 to 2024 reveals multiple interventions, corrosion issues, and performance challenges that prompted the adoption of a more robust solution. Frequent corrosion-related failures were observed in wells using conventional rod strings. Despite chemical treatments, corrosion persisted, leading to increased maintenance costs and reduced operational efficiency.

Application Details

The specific application involved a deviated wellbore with a measured depth (MD) of 3096m (10,158ft) and true vertical depth (TVD) of 1625m (5532ft). The maximum dog leg severity (DLS) was close to 12 degree/30m (100ft). The bottom hole pump assembly was landed at 1310m (4298ft) which is still in the vertical section of the wellbore at where the rod is exposed to minimal wellbore curvature. Side loads maxed out at 23lbs/ft near surface at 200m (656ft), and decreased below 10lbs/ft at 800m (2625ft) eventually falling below 3lbs/ft at 1200m (3937ft) to the pump landing depth.

The produced emulsion consisted of 35m3/day of total fluid with around 97% water, 3% oil (approximately 38 degree API) with trace amounts of abrasives. The bottom hole temperature is estimated to be around 40OC. Predictive analysis completed under these conditions on the 7/8” ND rod string showed 37% rod loading at a service factor of 1 using the T/2.8 rod equation in SROD.

Rod String History

In the previous 5 years leading up to the KeBond™ deployment, the rod string experienced multiple failures including rod breaks near the surface, tubing leaks, and pump changes due to bent pump components. Corrosion, particularly CO₂ related, was a recurring issue. Maintenance actions included upgrading to bare continuous rod followed by a rod sample failure analysis after multiple rod breaks occurred initially after 259 days in operation and then 22 days later.

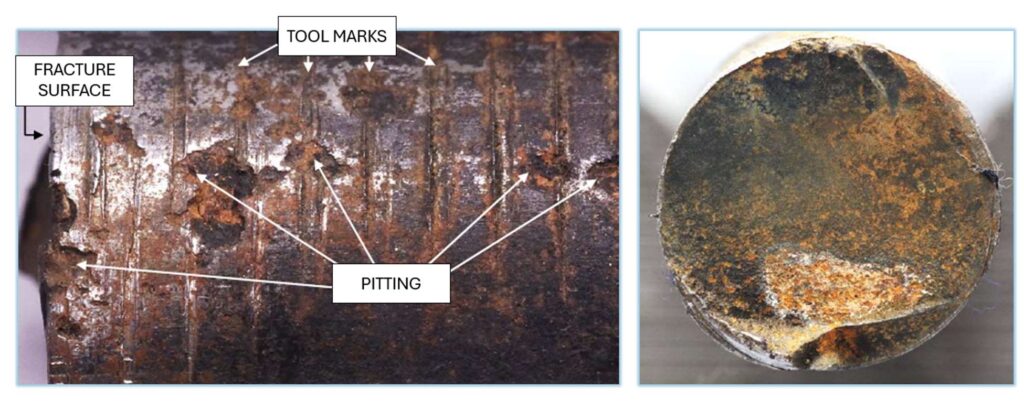

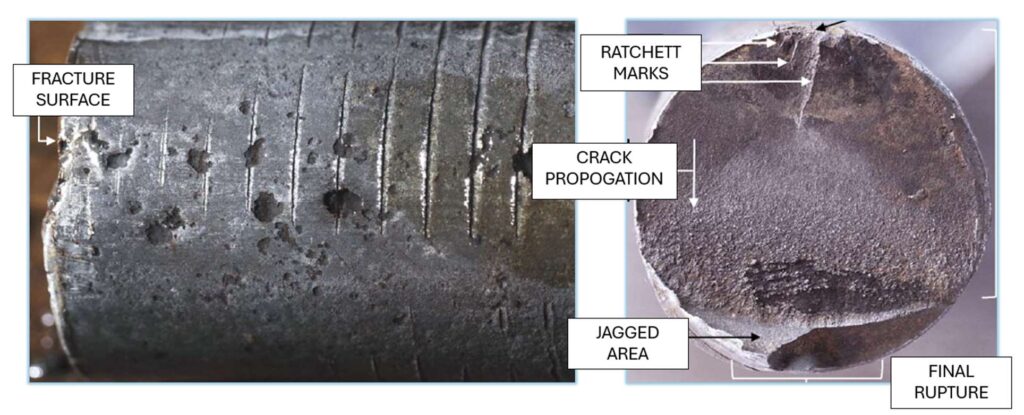

A metallurgical analysis of the bare continuous rod string (970N, Nickle Chrome Moly Alloy) failure on December 1, 2023, revealed high-cycle, low-stress fatigue initiated at a corrosion pit. The rod material met specifications, and the failure was attributed to CO₂-related corrosion. Energy dispersive x-ray (EDX) analysis confirmed the presence of iron carbonate scale and iron carbide particles. Despite the use of corrosion inhibitors, the rod failed due to environmental conditions including 2.4% CO₂ and 25 ppm H₂S. Images of the uncleaned and cleaned rod surfaces are shown in Figures 1 and 2 below.

Client Goals

Our Canadian client wanted to extend the historical bare Conventional and Endless Rod™ run times. Performance would be considered a success if KeBond™ improve well economics by reducing operating cost related to frequent rod parts and associated servicing expenditures related to rod string repair/replacement.

LS Solution

KeBond Coated Endless Rod™, developed by Lifting Solutions, features a polyketone-bonded composite coating that resists corrosion and wear. It is compatible with all ER rod grades and sizes, and operates in vertical, slant, and directional wells.

The coating is not field-strippable and is designed to extend runtime in aggressive environments. This specialty coated rod variant supports deployment of rod string weights up to 20,000 lbs with depths varying by rod diameter and effective rod weight per unit of length. The primary benefit of KeBond™ is to act as a barrier coating protecting the Endless Rod™ body from wellbore fluids and their associated corrosion damage including conditions where there is inhibitor wipe.

KeBond™ has also shown a lower coefficient of friction than bare steel which can reduce loads as well as reduce rod and tubing wear when subjected to similar deviated well conditions. KeBond™ was deployed to mitigate corrosion and mechanical wear. Its bonded coating reduced rod/tubing friction and improved durability. The rod was installed in a well with known corrosion challenges and monitored for performance and durability.

Operational Results

The KeBond™ string has demonstrated exceptional field performance so far and continues to outperform. After 174 days of continuous service, the rod string was surfaced for inspection due to a tubing failure. Upon retrieval, the KeBond™ rod was found to be in excellent condition with no visible wear and the barrier coating fully intact.

This confirmed the durability and protective capabilities of the KeBond™ coating in aggressive downhole environments. Following inspection, the rod string was rerun into the well and as of July 15, 2025 has accumulated a total of 279 days in service, continuing to perform reliably. This successful deployment highlights the long-term value and resilience of the KeBond™ solution.

Conclusion

The KeBond™ string has shown superior resistance to corrosion and wear, reducing the frequency of interventions and extending service life. Its performance validates the effectiveness of the bonded coating in harsh environments. Based on the successful deployment and inspection results, it is recommended to expand the use of KeBond™ strings in wells with similar corrosive conditions. Continued monitoring and data collection will further validate long-term performance.

Let’s solve your lift challenges.

Reach out and Experience Performance with Lifting Solutions.