pivotAL™ PC Pump field Success

Project Profiles

Project Information

| Client Name: | Confidential |

| Location: | Seibert West, Alberta, Canada |

| Field Application: | Crude Bitumen |

| Evaluation Period: | July 2025 |

| LS Products and Services: | PivotAL™ Progressing Cavity Pump |

Client Challenge

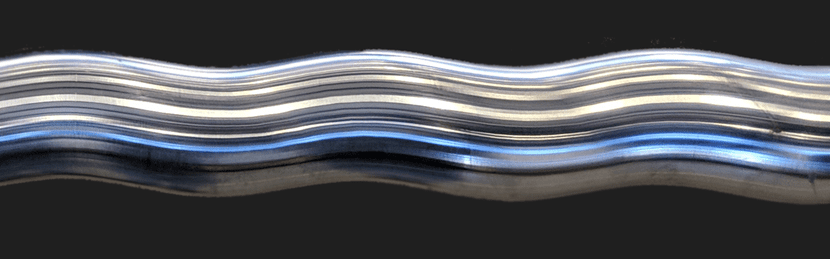

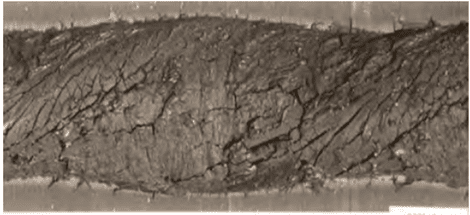

The production of viscous oil containing abrasive particles and sand presents significant operational challenges for artificial lift systems. High emulsion viscosity reduces reservoir inflow into the wellbore, limiting pump intake rates and impairing overall lift performance. In progressive cavity pump (PCP) applications, consistent cavity inflow and filling at the pump intake is critical for pump longevity. Insufficient filling can result in elastomer overheating, hardening, and premature pump failure due to inadequate lubrication.

While sand production is sometimes intentionally encouraged in processes such as Cold Heavy Oil Production with Sand (CHOPS) to enhance permeability and improve fluid mobility, it introduces additional complications. Abrasive solids accelerate elastomer wear, reduce volumetric efficiency, and shorten pump run life. These challenges often extend beyond individual wells, as fields developed from the same formation typically experience consistent issues across multiple producers. Frequent efficiency declines necessitate recurring workovers and pump replacements, depleting workover budgets and, in some cases, threatening field-wide economic viability.

conventional pcp failure well history

The wells in this specific field are faced with comparable issues caused by the presence of slow moving, viscous fluids with high abrasive content that lead to premature elastomer damage that declines pump performance. Across this field, a sample of 27 wells demonstrates an average runtime of approximately eight months, with the shortest observed runtimes being only 1.5 months which indicates a high frequency of pump failures and underscores the severity of abrasive wear and viscous fluid handling limitations in the current lift system design of conventional PCPs.

| Total Well Count | Average PCP Runtime | Lowest Average Runtime | Highest Average Runtime |

| 27 wells | 237 days | 47 days | 926 days |

Client Goals

The client’s objective was to extend pump runtimes in order to reduce workover frequency and associated expenditures. Performance improvements were to be evaluated on a well-by-well basis, with a target runtime increase of at least 30% established as the threshold for economic success. Achieving this improvement would decrease well downtime, enhance sustained oil production, and lower workover-related costs, thereby improving the overall economic viability of the field.

LS Solution

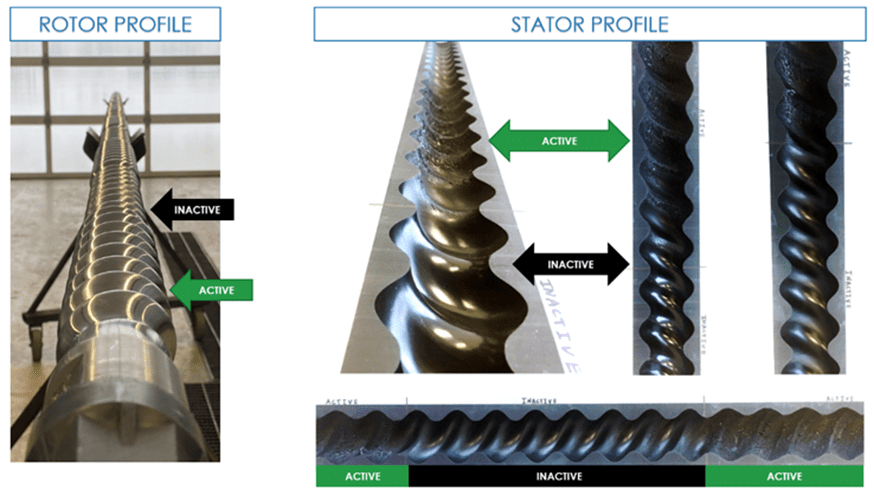

To address these challenges, Lifting Solutions deployed its PivotAL PC Pump across multiple wells. The PivotAL design incorporates an elongated stator and a custom-milled rotor with alternating active and inactive sections spaced at 12-inch intervals. When pump volumetric efficiency declines to a relatively inefficient state, the rotor can be repositioned into the previously unused stator section, restoring pump volumetric performance without requiring a service rig and its high associated costs.

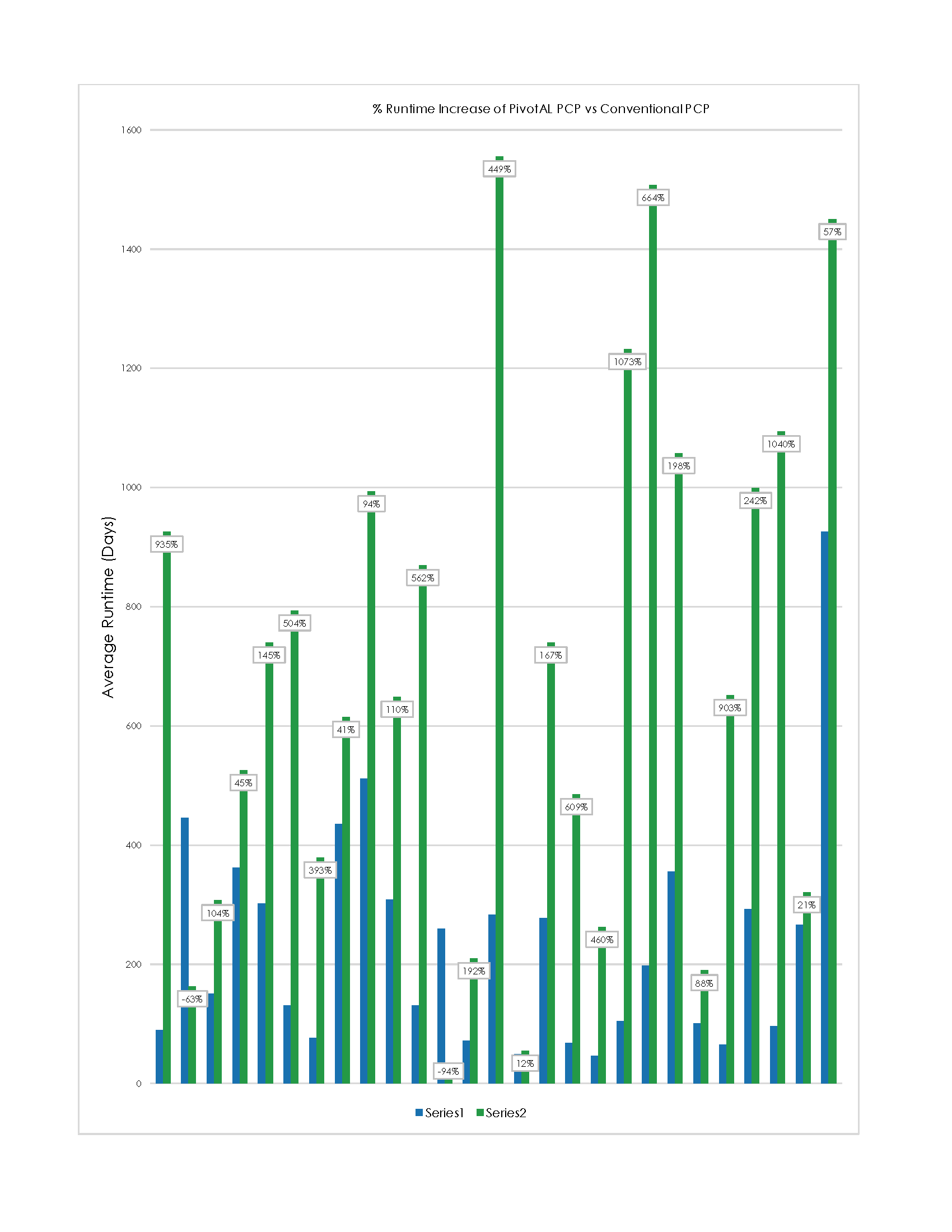

Across the 27 evaluated wells, performance was measured against key performance indicators (KPIs), with installations classified as either successful or unsuccessful (unsuccessful defined as PivotAL runtimes falling below the baseline conventional PCP runtime). Of the 27 wells, 25 achieved improved runtimes, and 23 surpassed the 30% improvement threshold for economic success. Only 2 wells underperformed relative to the baseline.

| Total Well Count | Wells w/ Improved Runtimes | Wells w/ No Improved Runtimes | Economic Success Wells (>30% Increase) |

| 27 wells | 25 wells | 2 wells | 23 wells |

On average, the PivotAL installations delivered a 331% increase in runtime compared to conventional PCPs, with several pumps continuing to operate beyond their KPI benchmarks as of July 2025. Figure 4 illustrates the well-by-well runtime improvements, with many applications exceeding the 30% economic benchmark by a substantial margin.

Conclusion

Through detailed collaboration with the client, the Lifting Solutions engineering and technical team developed a targeted solution to mitigate premature PCP failures caused by elastomer wear and fatigue. The introduction of the PivotAL PC Pump enables extended production runtimes across the field compared to conventional PCP installations. This technology is particularly suited for low-rate wells producing abrasive-laden fluids where accelerated elastomer degradation results in shortened pump life.

In this field, conventional PCPs demonstrated an average runtime of approximately eight months. Following the deployment of PivotAL PC Pumps, average well runtimes increased by a factor of ~4.3x, based on individual well performance improvements. This enhanced runtime significantly improves the field’s economic viability by reducing workover frequency, minimizing non-productive time, and lowering overall operating costs.

Let’s solve your lift challenges.

Reach out and Experience Performance with Lifting Solutions.