TAPERAL™ PC Pump Application Success

Project Profiles

Project Information

| Client Name: | Confidential |

| Location: | Peace River, Alberta, Canada |

| Field Application: | Bluesky Formation, Foamy Oil |

| Evaluation Period: | January 2026 |

| LS Products and Services: | TaperAL™ PC Pump |

Client Challenge

Undersaturated reservoirs are common in Canadian heavy oil applications, where the reservoir fluid consists of oil, dissolved solution gas, and connate water under pressure. In Cold Heavy Oil Production with Sand (CHOPS) operations, depressurization of the live oil below the bubble point induces exsolution of dissolved gas, leading to in-situ gas bubble expansion. This gas evolution serves as a primary production drive mechanism, displacing oil toward the wellbore. However, the rapid pressure decline and associated gas liberation often result in free gas generation or foamy flow behavior.

This process is governed by the Ideal Gas Law, where gas volume expands inversely with absolute pressure. Aggressive drawdown strategies like lowering fluid levels to reduce bottomhole pressure, promoting inflow, will amplify gas breakout and expansion. The increasing gas fraction within the produced emulsion introduces challenges for progressing cavity pump performance. Gas entrainment reduces pump volumetric efficiency, as free gas displaces liquid within the pump cavities. Additionally, the reduced lubricity and cooling capacity of gas-laden fluids accelerate stator elastomer damage. The increased cycles required to maintain production under these conditions further contribute to elastomer fatigue and premature failure.

To mitigate this low efficiency state, oversized pumps are often needed to lower the operational speeds required to effectively move fluid to the surface by compressing the gas back into solution at the discharge. However, this approach increases operational torque, transferring higher mechanical loads to the rod string and associated surface equipment.

A more effective practice is to minimize gas production at the pump intake by diverting or separating free gas prior to entry using a downhole gas separator. Gas separators can be difficult to optimize and size in applications constrained by casing diameter, high production volumes, or elevated fluid viscosity. In such conditions, alternative technologies are required to mitigate elastomer damage and extend pump run life.

Application Details

This application involved a horizontal multilateral well producing heavy, foamy oil from the Bluesky Formation, completed in 219.1 mm (8-5/8″) casing. Production design targets were 54 m³/d with a gas-oil ratio (GOR) of approximately 44 m³/m³ and BS&W of 16%. The dead oil viscosity was measured at approximately 12,000 cP with the oil API gravity measured at 10.2 degrees.

A GasAL™ downhole gas separator was evaluated but was not deployed because the elevated fluid viscosity and production rate were expected to limit gravity-based separation effectiveness for this configuration.

conventional pcp failure

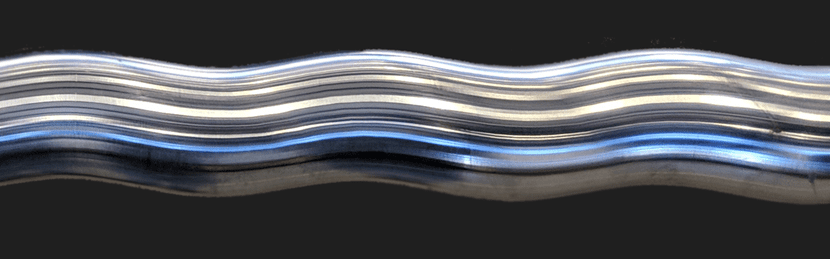

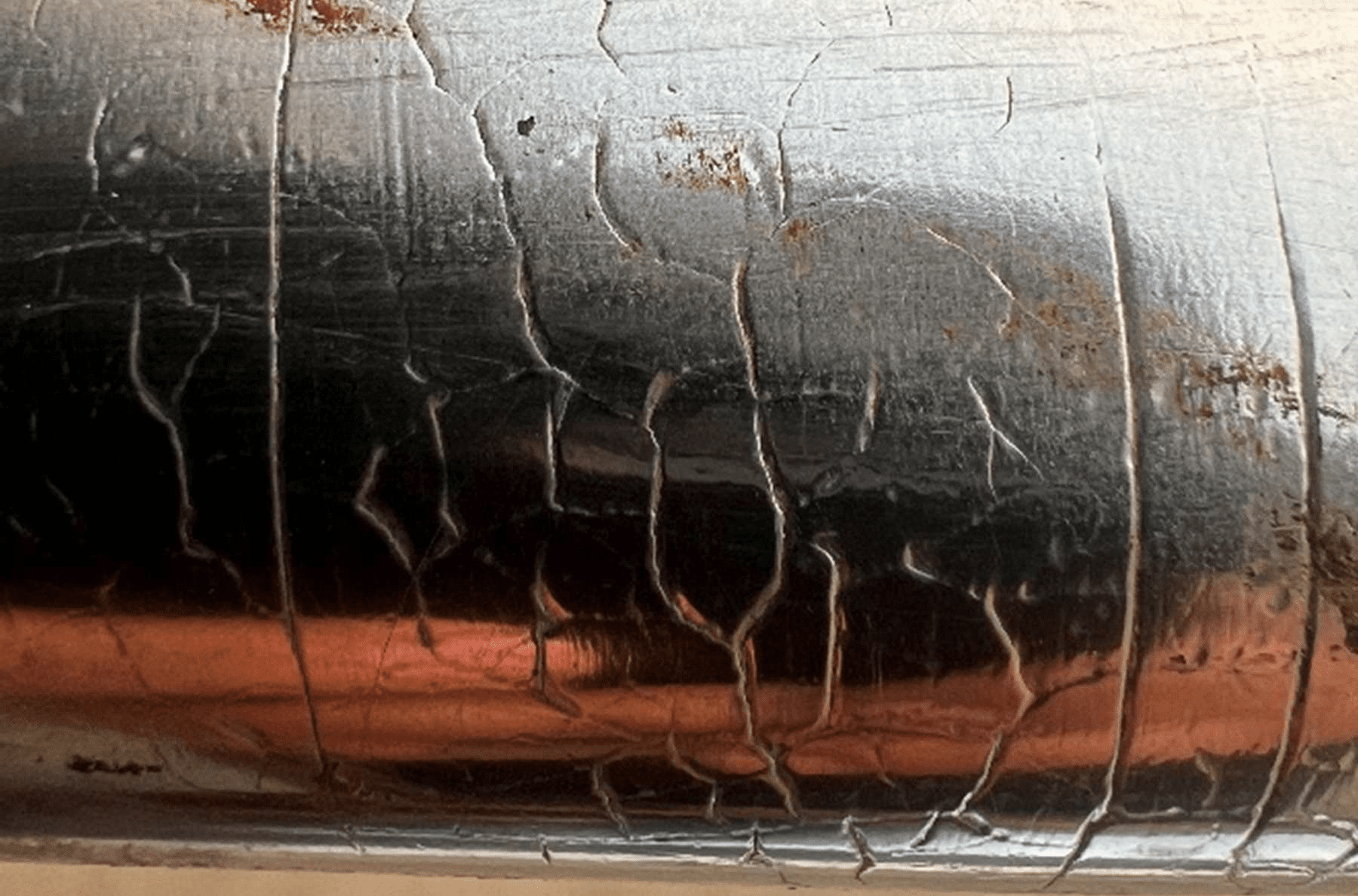

The previous installation utilized an 085-1500 series conventional PCP, which operated downhole for approximately 165 days. Upon retrieval, a Level 1 (L1) field inspection identified significant stator elastomer degradation, including thermal damage and missing elastomer in the upper half of the stator (Figure 2). The rotor also exhibited evidence of heat checking (Figure 3).

These failure mechanisms are characteristic of operation under high GVF fluid conditions. Loss of elastomer in the upper stator section indicates uneven pressure and load distribution along the pump length. In such scenarios, the discharge end of the PCP bears the majority of the compression work as it must recompress liberated gas back into solution. The localized concentration of mechanical and thermal stress accelerates elastomer failure and contributes to premature pump damage.

Client Goals

The client’s objective was to reduce the detrimental effects of high GVF fluid entering the pump intake and damaging the stator elastomer in order to improve operational longevity. Performance would be considered successful upon achieving a minimum 30% increase in runtime compared to the previous conventional PCP installation under similar operating conditions.

LS Solution

To meet these objectives, the Lifting Solutions Engineering and Technical teams collaborated with the client to implement a technology specifically engineered for wells experiencing gas-related PCP failures, the TaperAL progressing cavity pump.

The TaperAL PC Pump incorporates a tapered stator with a tight compression fit at the intake and a reduced compression fit at the discharge while utilizing a conventional rotor. The tapered geometry promotes uniform pressure distribution by preventing excessive localized loading and distributing the workload across the entire pump length. This design delays elastomer damage, particularly in high-GVF environments where conventional PCPs concentrate the majority of the recompression work of free gas back into solution at the discharge end. By reducing mechanical and thermal stress on the components, the TaperAL technology extends operational time and lowers the risk of premature failure, thereby reducing overall operating costs.

Following the workover of the 085-1500 conventional PCP, an 085-1250 TaperAL PC Pump was run in hole. The pump was selected for its enhanced performance and proven capability to operate in high gas volume fraction environments where conventional PCPs typically experience early failure.

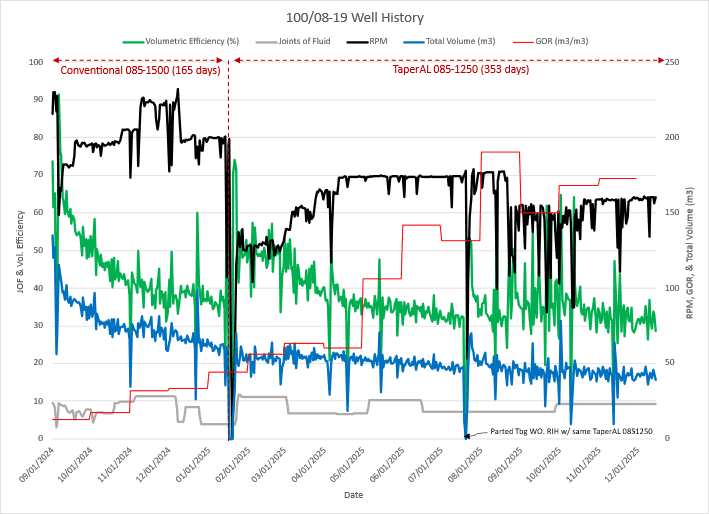

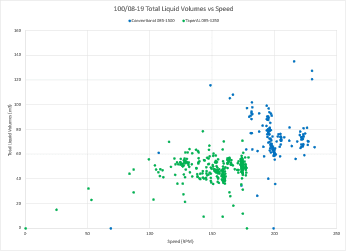

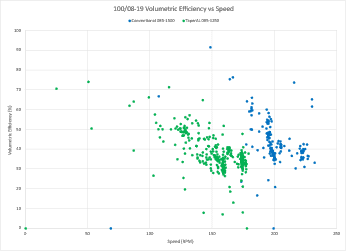

Operational data indicate that the conventional PCP and the TaperAL PC Pump were run under comparable conditions, although the prior installation was operated more aggressively at an average speed of approximately 200 RPM versus 175 RPM for the TaperAL. The higher speed likely contributed to the accelerated failure of the conventional PCP; however, the notable increase in total run days with the tapered stator demonstrates a clear design benefit.

The slightly higher volumetric efficiency recorded during the conventional PCP period is attributed to the increased operating speed and the recovery of completion fluid, as the conventional PCP was a new well completion (NWC) installation.

As of January 2026, the 085-1250 TaperAL PC Pump remains in continuous operation. The well has required only one intervention, a parted tubing repair. The TaperAL PC Pump was inspected during this service job, reinstalled, and has operated reliably since the workover.

Conclusion

Collaboration with the client enabled the development and deployment of an effective gas-tolerant PCP technology for this heavy, foamy oil application. Implementation of the TaperAL PC Pump increased pump longevity from 165 days with a conventional PCP to 353 days (and counting), representing a 114% increase in run days or a ~2.1x relative improvement in runtime.

Because the tapered stator technology evenly distributes the workload along the entire pump length rather than concentrating stress at the discharge end, pump runtimes are effectively improved. This extended runtime improves economic viability by reducing workover frequency, minimizing non-productive time, and lowering operating costs.

Following the success of this installation, additional TaperAL PC Pumps have been deployed across the client’s field, with comparable positive results observed in subsequent wells (most paired with a GasAL and the others without). Ongoing monitoring and performance data collection will continue to validate the long-term runtime benefits of TaperAL technology under similar conditions.

Let’s solve your lift challenges.

Reach out and Experience Performance with Lifting Solutions.