PivotAL PCP Model 10-1200X2 100/11-10

Project Information

| Location: | Elk Point, Alberta, Canada |

| Field Application: | CHOPS (Cold Heavy Oil Production with Sand) |

| Products: | PivotAL Progressing Cavity Pump* |

| Install Date: | October, 2017 |

Client Challenge

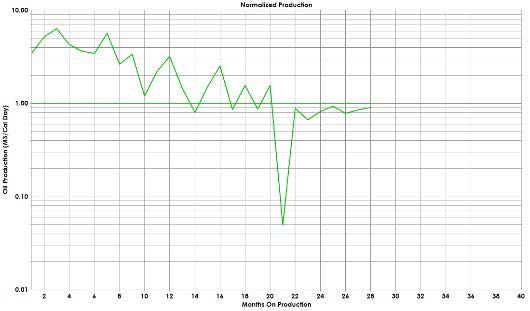

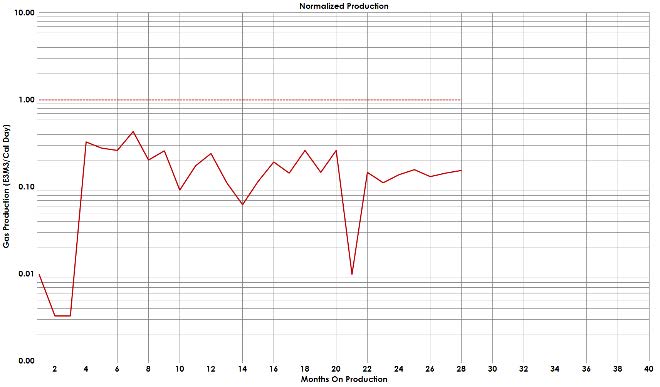

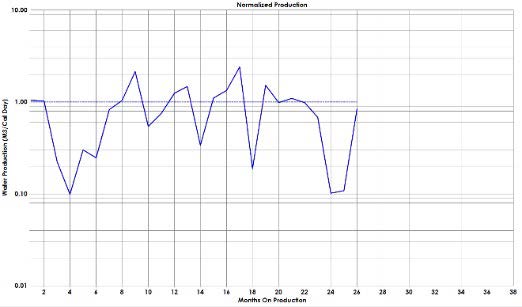

In a CHOPS (Cold Heavy Oil Production with Sand) application near Elk Point, Alberta our Client was experiencing short run times on a well that was recompleted in May of 2017. The well was making 5-6m3 of oil daily for the first 6 months after recompletion. The well steadily declined over the next few years and has settled into a marginal rate below 1m3 of daily oil. Overall water cut was relatively low over this time with little to no water being produced. On the normalized production plots below, the LS Pivotal pump was installed in the 6th month.

Client Goal

The previous PCP installed in this application ran for 4.5 months. The Client was looking for options to increase run time and decrease workover frequency in order to improve the economics on this well.

Our Solution

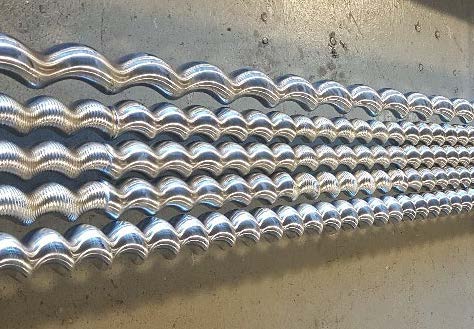

The patent pending Lifting Solutions PivotAL PC Pump was evaluated as a viable option to reduce the frequency of tubing pulls effectively decreasing workover costs. A model 10-1200×2 PCP was deployed on October 27, 2017 and began producing around 6m3/day of total fluid with 87% oil, 6% water and 7% sand. Monthly updates over the course of the next 8 months are summarized in the table below.

| Month | Position | Operational Notes |

|---|---|---|

| OCT 2017 | P1 (INITIAL) | Pump began operating at 85% efficiency. |

| NOV 2017 | P1 | No major updates. Pump was running at >80% efficiency. |

| DEC 2017 | P1 | Pump continues to perform, frequent blocked intakes reported due to significant sand production. Numerous flushes required. |

| JAN 2018 | P1 (108 DAYS) | Average production efficiency has been 75%. Efficiency was dropping around January 15, 2018 but was restored back to 85% with a flush and well load. Operator was aggressively trying to pump off the well. Performance response to well loading indicated that the emulsion contained a bit of gas. Sand cut continued to be around 7%. |

| FEB 2018 | P2 (LIFTED 12”) | Scada trending shows that the pump intake appears to regularly choke off. Flushing and well loading continue as a preventative measure to restore/maintain efficiency. After a super flush on February 12, 2018 the rotor was re-landed in the second position 12in above the previous landed location. |

| MAR 2018 | P2 | Pump continues to run with periodic intake blockages. Evaluation of the producing scada trend in February indicated that the pump was still producing good in P1, and that the lift may have been unnecessary. |

| APR 2018 | P2 | Pump continues to produce in the second position. Previous PCP runtime has been exceeded. Intake issues appear to be happening at a lower overall frequency as there are less flushes/well loads happening. |

| MAY 2018 | P2 | No major updates. Pump continues to run in the second position at around 70% efficiency. Well was flushed on May 9th, with a pump pressure test indicating that the pump is wearing out. (500psi to 0psi in 45 seconds, normally the pump would hold pressure longer). |

| JUN 2018 | P2 | Pump efficiency is starting to decline. Discussions with the engineer about lowering the rotor back down into P1 to see if efficiency is restored. |

| JUL 2018 | P2 (PULLED) | Pump was pulled on July 2, 2018 due to poor pump efficiency in the second landed position. It was not lowered back into the first position unfortunately. |

Conclusion

The installation of the PivotAL pump was considered a technical success as the pump efficiency was restored by the rod lift operation. There was a positive run time performance increase from 4.5 months up to 8 months. This equates to a reduction in servicing frequency from 2.7 times/year or $40,000/year down to 1.5 times/year or $22,500/year based on an average workover cost of $15,000. This is a potential savings of $17,500/year.

*PivotAL is a registered trademark. Patent No.: US 11,499,549 B2. Canadian patent pending.

Let’s solve your lift challenges.

Reach out and Experience Performance with Lifting Solutions.