EnerSaver FL1741 Generative Drive Reduces kWHrs and Demand

Project Information

| Location: | 3 wellsites in South Saskatchewan, Canada |

| Application: | Heavy-Medium Crude Oil |

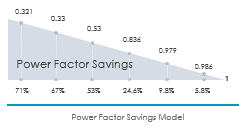

| Wellsite Observations(s): | Significant harmonics Previously installed power factor correction capacitors were not operating effectively. Wellsite power factors: Wellsite 1: 0.979 PF Wellsite 2: 0.836 PF Wellsite 3: 0.986 PF |

Client challenge

At three wellsites, our client was experiencing poor power quality that caused multiple

power bumps drawing from grid infrastructure. This resulted in high demand charges

and growing power costs with an annual 5% increase.

client goals

Our client wanted to optimize operations at their wellsites by:

- Reducing consumption and demand on the existing power grid

- Decreasing the cost on their monthly utility bill (stroke per stroke basis)

- Reducing their carbon footprint and becoming CO2 offset eligible*

the ls solution

Rotor breaks require pulling of the tubing to repair resulting in expensive workover operations. At a minimum of $20,000 to surface the tubing and replace the pump, continued premature rotor breaks will result in a well becoming uneconomic. Once the well has been drilled, not much can be done about the wellbore trajectory and resulting dog leg severity. Changing conditions downhole over time result in shifting of the casing which can also lead to misalignment of the rotor and stator during operation downhole. With limited options available, our client looked to Lifting Solutions for options. Reverting to basic engineering principles for rotating shafts, we went to work on a fundamentally different pump geometry – a very ‘large’ idea that did not fit in with historical PCP design philosophy (low d/e, high eccentricity, weak rotors with optimized geometry focused on volume efficiency).

LS SOLUTION

Lifting Solutions implemented an EnerSaver FL1741 drive field trial involving:

- Selecting candidate sites based on power costs and readings of existing equipment (harmonic distortion, power factor, and KVA demand).

- Installing at each site the following equipment:

- ron® SENTINEL® power meter (collected data on existing equipment)

- NEMA B premium efficiency motors

- EnerSaver generative drives, connected to the grid (collected data with Itron SENTINEL power meter)

After the trial, it was determined that the EnerSaver drive lowered demand charges by 14% (average), kWh by 18% (average), improved power quality and overall efficiency of the electric motor and reduced harmonic distortion.

key performance indicators

By achieving a power factor of 1, the client was able to save:

- 7.6% on demand charges and 19.8% on kWh at Wellsite 3

- 9.8% on demand charges and 13.7% on kWh at Wellsite 1

- 24.6% on demand charges and 23.4% on kWh at Wellsite 2

The EnerSaver FL1741 generative drive acted as a micro-generator and went from consuming KVAR to generating KVAR back to the grid, which also improved the performance of existing equipment.

*In jurisdictions where renewable status is applicable

Let’s solve your lift challenges.

Reach out and Experience Performance with Lifting Solutions.