HN2 Elastomer in Swift Current

Project Information

| Location: | Swift Current, Saskatchewan, Canada |

| Application: | Medium Grade Oil, High Water Cut (WC) |

| Initial Install Date: | August 2020 |

| Product(s): | Progressing Cavity Pumps with HN2 Elastomer |

Increase operational time ~2.5X with the right elastomer & optimize well performance!

CASe summary

The optimal performance of a pump depends on having the right elastomer. Lifting Solutions’ client was looking for a more efficient way to extract medium-grade oil from their wells that also had a high water-cut ratio (water produced vs oil produced) using a Progressing Cavity (PC) Pump application.

Our client was using one of our High Nitrile Elastomers, HN1, at the time but it wasn’t getting the longer-term results needed. This challenge allowed Lifting Solutions’ engineering and technical team to investigate a new opportunity—the development of a new elastomer that improved initial pump efficiency using a low swell formulation while maintaining robust mechanical properties.

Our High Nitrile, HN2, elastomer was developed exclusively as a solution to their challenge. Applications started with a much higher efficiency and are seeing decreasing well interventions, increasing operational time, and decreasing operational expenses.

BACKGROUND – THE WELL ENVIRONMENT

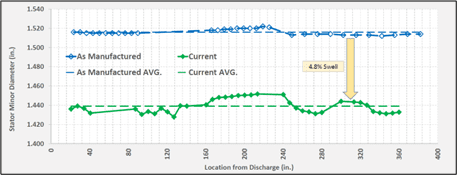

Several producing formations in the Swift Current area of Saskatchewan cause significant elastomer swelling and hardness changes. If incorrectly estimated, elastomer swell will reduce pump performance and longevity. The baseline efficiency of the pump is an important factor in the pump selection process, including compensation for elastomer/fluid swell. There are four possible rotor/stator sizing scenarios each having a different performance effect as outlined below in Table 1.

| ROTOR SIZING | SWELL ESTIMATION | PERFORMANCE STATE | PERFORMANCE EFFECT |

|---|---|---|---|

| Undersized | Underestimated (low overall) | Low pumping efficiency | Under compression, slippage, wear, and fluid washing |

| Undersized | Overestimated (high overall) | Adequate pumping efficiency | Adverse elastomer effects of high swell |

| Oversized | Underestimated (low overall) | Adequate pumping efficiency | Ok |

| Oversized | Overestimated (high overall) | High operating torque | Over compression, increased friction, and wear |

The process of initial swelling can take anywhere from several weeks to one month, depending on a variety of factors. During this time, the pumping system can operate in an inefficient state as swell begins to increase toward adequate compression fit. This leads to slippage, wear, and fluid washing.

In contrast, the swelling process can result in an excessive compression fit and cause high pump torque, significant wear, the hysteresis of the elastomer, and missing rubber.

In the Swift Current region, produced fluids contain elements that cause significant swelling of the elastomer. These elements can be high-water cuts, medium-grade API oils, and potential free gas. Originally the high nitrile (HN1) elastomer was the best fit for this area as it has mechanical and dynamic properties capable of handling the wellbore environment. Traditional PC Pump applications take place in low API heavy oil fields and use medium nitrile elastomers due to the absence of fluid swell and the requirement for abrasive resistance. High nitrile elastomer is better designed for medium-grade, high aromatic content oil applications. The typical application approach was to target a low baseline efficiency in anticipation of significant fluid swell.

CLIENT CHALLENGE

Prior installs with the HN1 elastomer led to positive run times in the area, however, there was poor initial performance and inconsistency because of the variability of high swell rates. A low-swelling HN2 elastomer has better optimization potential. Increasing initial production rates and preventing pump failures reduces OPEX costs and increase run time/production rates. Our short- and long-term goals were to increase production, have longer run times, and prevent costly workovers. With significant historical operational data in the area, Lifting Solutions began work on an elastomer formulation that would improve pump efficiency from day one, and remove ambiguity from pump sizing with a swell-resistant pump system offering.

THE LS SOLUTION

Lifting Solutions’ engineering team underwent the development of the HN2 elastomer to better suit applications with similar conditions and problems. Numerous materials testing methods were conducted, such as fluid compatibility testing, to strategically analyze the changes in variations of high nitrile elastomers. The final product, a result of 160+ analyzed and tested formulations, is the Lifting Solutions’ HN2 elastomer. HN2 demonstrates superior mechanical properties as shown in Table 2.

ELASTOMER CLASSIFICATION AND PROPERTIES

| PROPERTY | STANDARD | UNITS | SOFT NITRILE (SN1) LS ELASTOMER | MEDIUM NITRILE (MN1) LS ELASTOMER | HIGH NITRILE (HN1) LS ELASTOMER | HIGH NITRILE (HN2) LS ELASTOMER |

|---|---|---|---|---|---|---|

| ACN Content | ASTM D5508-16 | % | 30-35 | 30-35 | 40-45 | 30-35 |

| Specific Gravity | ASTM D792 | Unitless | 1.18 | 1.23 | 1.23 | 1.21 |

| Hardness | ISO 7619-1 | Shore A pts | 58 | 68 | 73 | 73 |

| Ultimate Tensile Strength | ASTM D412 | PSI | 2089 | 2384 | 2444 | 3047 |

| Ultimate Elongation at Break | ASTM D412 | % | 854 | 594 | 445 | 570 |

| Tear Strength | ASTM D 624 -T | lbs./in | 141 | 126 | 80 | 73 |

| Unaged Stator Bonding – Rubber Retention | ISO 15136-1 A.4.5.1 | None | R100 | R100 | R100 | R100 |

| Maximum Operating Temperature | – | °C | 60 | 80 | 80 | 100 |

| Maximum API Gravity | – | degrees | 15 | 20 (25*) | 30 (35*) | 35 (40*) |

In comparison to HN1, HN2 has a much lower swell in higher API gravity oils and associated levels of aromatics. Swell due to water is slightly higher with HN2 due to the polymer changes required for better oil resistance. Increased water swell can be viewed as trivial in an oil and water composition. (Refer to Table 3 and Table 4 for additional details.)

The bond strength of the HN2 elastomer was another key focus in development resulting in significant improvements, notably, in terms of bond retention in high-temperature fluids to simulate extended downhole exposure to higher temperatures.

| FLUID | TEMPERATURE | API GRAVITY | HN1 | HN2 |

|---|---|---|---|---|

| WATER | 100oC | n/a | 4.8 | 6.5 |

| WATER | 80oC | n/a | 3.4 | 5.5 |

| WATER | 60oC | n/a | 3.2 | 4.1 |

| IRM 903 | 100oC | 23 | 6.2 | -0.7 |

| IRM 903 | 60oC | 23 | 3.3 | -1.2 |

| DIESEL | 60oC | 38 | 16.1 | 6.5 |

| FUEL B | 30oC | 55 | 25.4 | 14 |

| FLUID | TEMPERATURE | API GRAVITY | WATER CUT (%) | HN1 | HN2 |

|---|---|---|---|---|---|

| C1F1 | 50oC | 19 | 30 | 6.6 | 3.6 |

| C1F2 | 50oC | 21 | 80 | 4.9 | 2.7 |

| C1F3 | 50oC | 22 | 85 | 3.9 | 2.4 |

| C1F4 | 50oC | 21 | 97 | 3.5 | 2.2 |

| C2F5 | 60oC | 38 | 0 | 6.7 | 2.7 |

| C3F6 | 50oC | 26 | 70 | 5.5 | 3.0 |

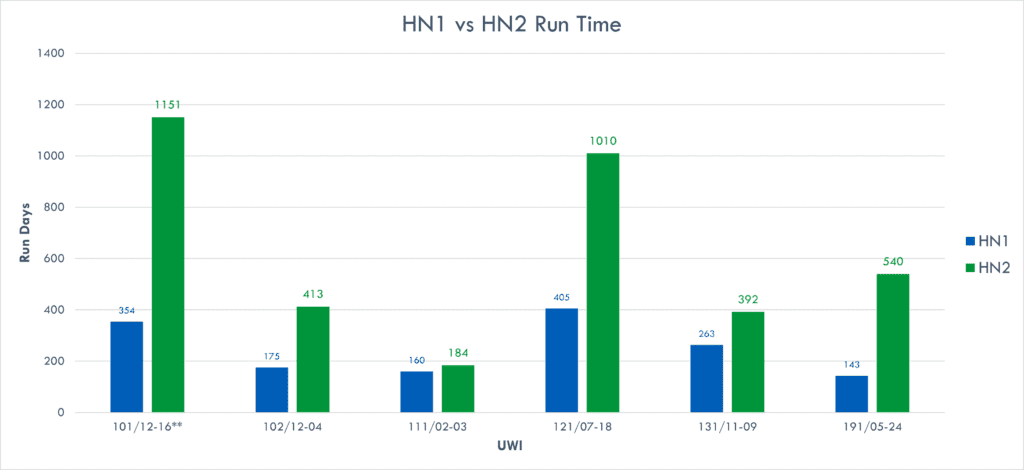

Lifting Solutions continues to monitor field results of our initial installation and the findings continue to show a significant runtime improvement of over 2.5x as shown in Figure 2.

CONCLUSION

Lifting Solutions’ development of the HN2 elastomer continues to succeed in the field. Our team understands the importance of having the right elastomer to optimize the performance of a Progressing Cavity Pump application. Contributing factors include higher initial production efficiency in the early stages of elastomer swell, less margin of error on initial sizing due to the lower overall swell rates, longer run times associated with improved elastomer mechanical properties and swelled rotor/stator fit. The optimal sizing state gained with the improved elastomer is effective at preventing premature failures related to excess slippage, fluid washing and accelerated wear

Let’s solve your lift challenges.

Reach out and Experience Performance with Lifting Solutions.